Researchers Liu Jing and Wang Lei describe a liquid phase 3D printing technique for rapid manufacturing of a conductive metal object in their study published by the journal Science China – Technological Sciences.

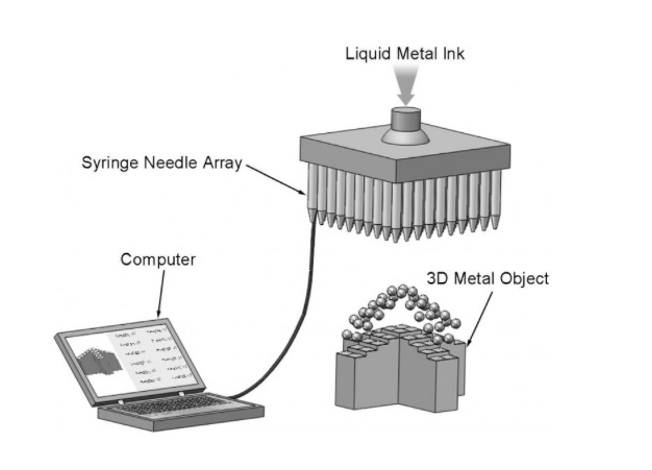

Their study entitled “Liquid phase 3D printing for quickly manufacturing conductive metal objects with a low melting point alloy ink”, describes the process of how metal printing ink is dropped into a liquid phase cooling fluid via injection needles to create a three-dimensional object. Several Factors during the process affect the quality of the final result: properties of the cooling fluid, air pressure within the syringe barrel and needle diameter as well as types and properties of the printing ink. Any metal with a low melting point (less than 300°C) can serve as a printing ink, however, a corresponding cooling liquid must be available. The material can be an alloy based on gallium, bismuth or indium. It is also possible to use a mixture of these alloys with nano particles. Compared with air cooling used in conventional 3D printing methods for metal, this liquid phase cooling fluid manufacturing process prevents the metal ink from oxidation.

The new technique is supposed to own potential values not available in conventional methods and could therefor open an efficient way for quickly manufacturing conductive metal objects in the near future.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.