The Dutch company Admatec has developed their ceramic 3D printer even further and introduces ADAMAFLEX 2.0.

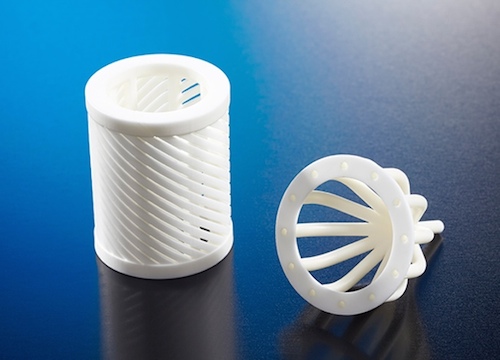

The ceramic 3D printer is capable of creating objects with a precision of +/-0.3% variance from the actual CAD model and surface finishes with a Ra value of 1 micrometer.

The company has already implemented this technology for their current orders from the endoscopy market but will most likely also supply the dental and microreator markets. ADAMAFLEX 2.0 is based on the stereolithography 3D printing method, where liquid photopolymer mixed with ceramic powder is cured by a UV laser. This technique allows for very precise results of objects.

Admatec is hoping to become a leader in the field of ceramic printing and is already able to produce 15,000 of such parts faster and more economically than it would be with traditional injection moulding techniques.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.