3D Biofabrication is an emerging application field of high-precision 3D printing based on Two-Photon Polymerization (2PP). In 3D Biofabrication, cells are utilized as building blocks to precisely construct living materials, such as tissues, for pharmaceutical and regenerative medicine applications. Now, BIO INX and Nanoscribe are launching a new bio resin (HYDROBIO INX N400) enabling printing in the presence of living cells.

In low resolution extrusion-based bioprinting technologies, there are a plethora of available inks that can be made into cell-laden bioinks. However, there are few commercially-available photoresins for Two-Photon Polymerization that can be mixed with cells to create cell-laden bioresins. Nanoscribe’s high-resolution technologies are already demonstrating their enormous application potential, especially for mimicking the architecture and complexity of natural tissues.

With the launch of Hydrobio INX N400, the first commercially-available bioresin that enables cell encapsulation in 3D printing with Nanoscribe’s Photonic Professional systems, additional complexity can be introduced.

“The ability of cell encapsulation, in combination with cell seeding, allows for the generation of complex multicellular tissues which mimic the architectural complexity of natural tissues.” – Agnes Dobos, application specialist at BIO INX.

With this product, the field of high-resolution biofabrication is further opened, as Nanoscribe Photonic Professional systems are used by more than 3,000 experts in science, research and industry worldwide. Now, finally, users of Nanoscribe systems can fully leverage the potential of Two-Photon Polymerization for biomedical applications.

“Until now, you had to add inorganic additives to our photoresins to obtain functional materials. With the introduction of Hydrobio INX N400, our customers now benefit from a proven product with the ability to encapsulate cells as living ingredients for 4D materials,” states Remmi Baker-Sediako, Life Sciences Business Development Manager at Nanoscribe.

Furthermore, the high precision and ability of two-photon lithography to print directly into microfluidic chips, makes this bioresin ideal for organ-on-chip applications. Here, cell encapsulation is key to generate more realistic microorgans. With Hydrobio INX N400, users can mix their specific cells with the photoresin to produce customized cell-loaded bioresins. Additionally, the resin loses its autofluorescence after 7 days in culture, resulting in better live cell imaging capabilities. Therefore, the new bioresin can help to bring about a paradigm shift in the field of drug screening and drug discovery applications. As a result, this new resin brings the field one step closer to reducing the number of animal trials needed in drug development.

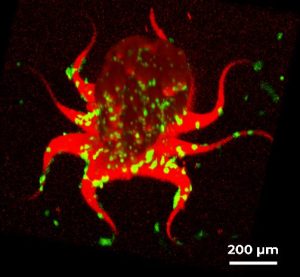

Printing of more complicated architectures: a blood vessel printed using HYDROBIO INX N400 in the presence of fibrosarcoma cells after 1, 7 and 14 days (when the autofluorescence of the material is gone) in cell culture.

“The combination of the expertise at BIO INX for biomaterials development, with the world leading expertise of Nanoscribe in the development of cutting edge two-photon lithography equipment can generate a paradigm shift in the field of biofabrication thereby bringing the technology closer to real life applications.” – Jasper Van Hoorick, CEO of BIO INX.

For more information about BIO INX, visit www.bioinx.com.

To learn more about Nanoscribe, please visit www.nanoscribe.com.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.