Desktop Health, a brand of Desktop Metal, Inc. (NYSE: DM) specializing in medical 3D printing, has announced that the first patients have been treated with CMFlex. This market-ready, 3D-printed synthetic bone graft substitute was designed and manufactured on the 3D Bioplotter by Chicago-based Dimension Inx.

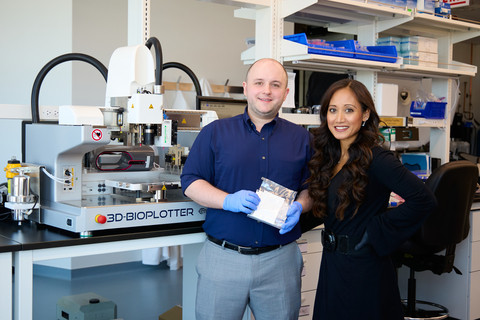

CMFlex is a joint invention of Dimension Inx co-founders Dr. Ramille Shah, CSO and Head of R&D, and Dr. Adam Jakus, CTO and Head of Technology Strategy. The duo has been working on the development of the material and product on the Desktop Health 3D Bioplotter since 2009.

Dimension Inx, founded in 2017, is a regenerative therapeutics company that designs, develops and manufactures therapeutic products to restore tissue and organ function. The company owns four Desktop Health 3D bioplotters – two for R&D and two for manufacturing their commercial product CMFlex.

In December 2022, Dimension Inx received FDA clearance for CMFlex. CMFlex is currently available to a limited number of leading surgeons, with a wider market launch planned for 2024.

The first jaw applications were performed by Dr. Derek Steinbacher, Director of the West River Surgery Center, and Dr. Brian Farrell, DDS, MD, of the Carolinas Center for Oral & Facial Surgery. Procedures included mandibular angle augmentation and maxillary segmental osteotomy.

CMFlex was also used by Dr. Robert Bosack, DDS, for dental socket maintenance surgery in preparation for future dental implants.

“These first cases are not only indicative of a new generation of biomaterials, but also highlight our technology platform’s unique capability to rapidly create biomaterials that direct cell behavior to restore tissue and organ function. It is a proud moment for us to be able to demonstrate the value of therapeutics derived from integrating novel biomaterial design and 3D-printing approaches,” said Dr. Adam Jakus, CTO, Head of Technology Strategy, and Dimension Inx co-founder.

Dr. Ramille Shah, CSO, Head of R&D, and co-founder of Dimension Inx, added, “We’re excited by the interest we’ve already received from surgeons who recognize the importance of a ready-to-use solution with great handling characteristics and the ability to cut and shape the graft to match the defect site.”

This development marks an important advance in the medical application of 3D printing technologies and shows the potential to revolutionize the treatment of bone and tissue defects.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.