Following his other two projects, the 3D printed Minion and Spongebob, Dalibor Pejicic shares his latest project in cooperation with Josip Jakubiv with the community. This time his 3D modelling and printing project has a very practical approach, that could also save you some money:

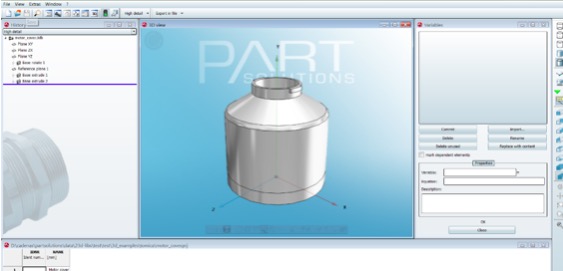

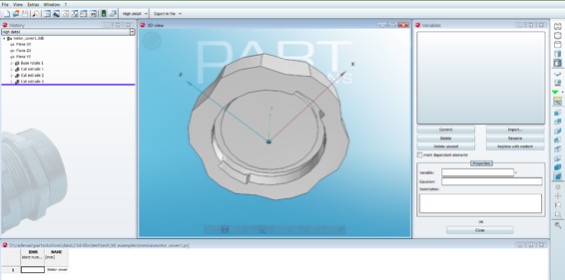

On this photo we can see TRW pump used for hydraulic power steering. The plastic oil tank and lid were damaged in car accident, so our goal is to make a new one using 3D modeling and printing technology.

PARTsolutions software is our choice, because it is easy to use and it gives great results. All dimensions/parameters are adjusted to our needs, so it will fit perfectly to the TRW pump. Both parts are published on PARTcloud.

It takes 1 hour for the lid and approximately 5-6 hours for the oil tank to be printed. We are satisfied with the results and it is time to test it.

The oil tank has to be sealed first and it is time to put some oil in it and to check for a possible leakage. Everything is functioning well and our goal is achieved. This is a good example how 3D modelling and printing can be used in automotive area and save your home budget, too.

Would you like to contribute a guest post as well? Please contact us!

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.