Sculpteo, the factory in the cloud specializing in online 3D printing and digital manufacturing, is innovating yet again by revealing a new offer of laser cutting to allow a global manufacturing service in an era where the digital has triumphed.

Via its online 3D printing service, Sculpteo already offers more than 50 materials allowing to manufacture porotypes and small series. With tools such as Smoothing Beautifier, Batch Control, Hollowing or Final proof, Sculpteo offers a wide range of services allowing to accelerate and optimize the process of manufacturing, as well as make it more competitive than traditional manufacturing methods. By including the laser cutting, Sculpteo wishes to offer a service that allows the manufacturing of 100% of the products online.

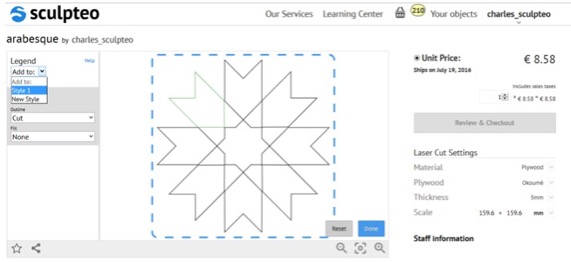

Sculpteo has realized that 40% of the products manufactured by its users contained elements manufactured by laser cutting. In consequence, users had to pass through another supplier to manufacture these parts through laser cutting. Now, when a user loads its CAO file on the Sculpteo platform, he is automatically offered the manufacturing technique that is best suited for his design. Other than its complete online 3D printing service, Sculpteo also offers laser cutting for the following materials: wood, cardboard, Plexiglas. By focusing these different manufacturing techniques on its platform, Sculpteo allows not only to optimize the cost of manufacturing the products, but also to gain an average of 3 days for every stage of the iteration. The use of digital manufacturing for the production of series is a reality for a lot of entrepreneurs.

The interface was thought to allow the user to configure and optimize himself his production. He can change the file settings online without any software, he can reduce the price and, in the end, he only pays for the real quantity of materials used, in comparison with other services.

Alexis Williams, technical director of Hublex says “The cost/time of laser cutting remains far more interesting than the one of traditional manufacturing or other methods. The use of the parts resulting from laser cutting requires thinking a design that I could define as 2D and allows to produce a 3D by assembly. In consequence, this process is a very good method to create/design differently, in a clever way, and can have important economic benefits!”

Clément Moreau, CEO and cofounder of Sculpteo says: “Since the launch of Sculpteo in 2009, we haven’t stopped innovating by developing a software that allows to accelerate the manufacturing process via 3D printing, by offering new materials and finishes to better suit the demands of our users. By including laser cutting Sculpteo confirms its will to be the unique platform that satisfies the demands of industrials to manufacture regardless of the materials they want to assemble and in the fastest way.”

Laser cutting is already offered at the Sculpteo factory in Villejuif.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.