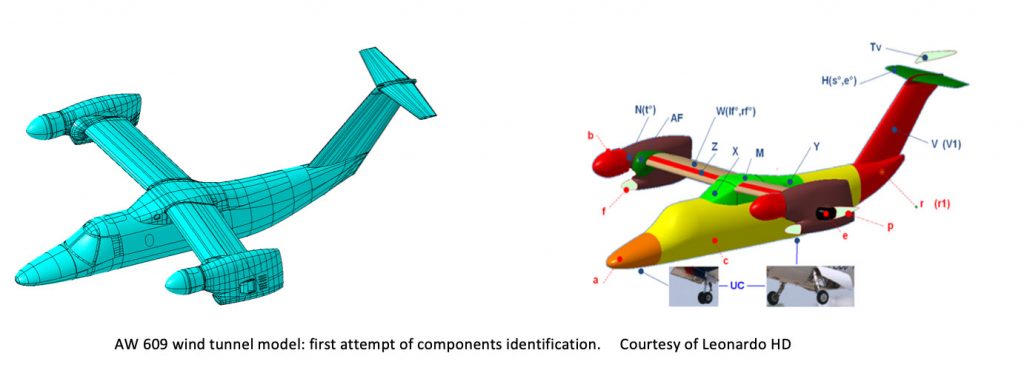

Among the most interesting and significant applications in the aerospace sector, developed thanks to the collaboration of our partners, is with no doubt the new wind tunnel model of the LEONARDO tiltrotor AW609 manufactures by CRP Technology for Leonardo Helicopter Division (Leonardo HD, formerly known as Agusta Westland).

This project allowed CRP Technology, once again, to highlight the perfect union between advanced 3D printing technology (Selective Laser Sintering) and Windform® high-performance composite materials. Thanks to the Windform® materials, it was possible to complete and test the model in the wind tunnel within a very short time, with excellent results and with high-performing mechanical and aerodynamic properties.

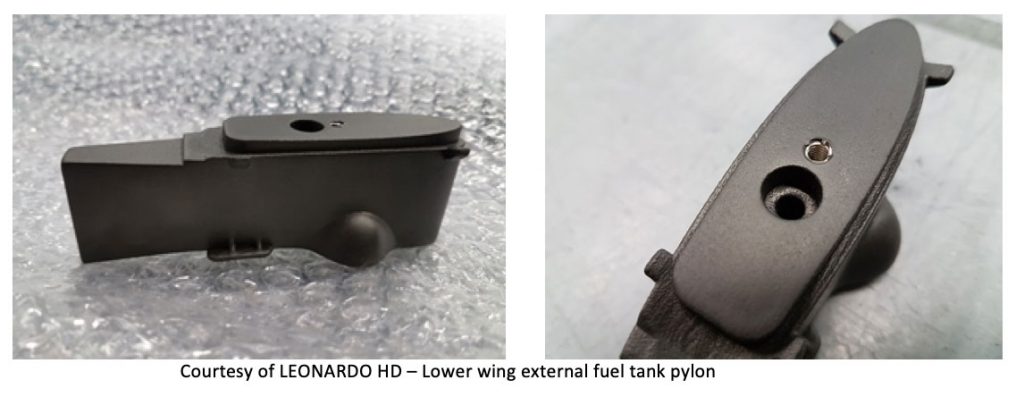

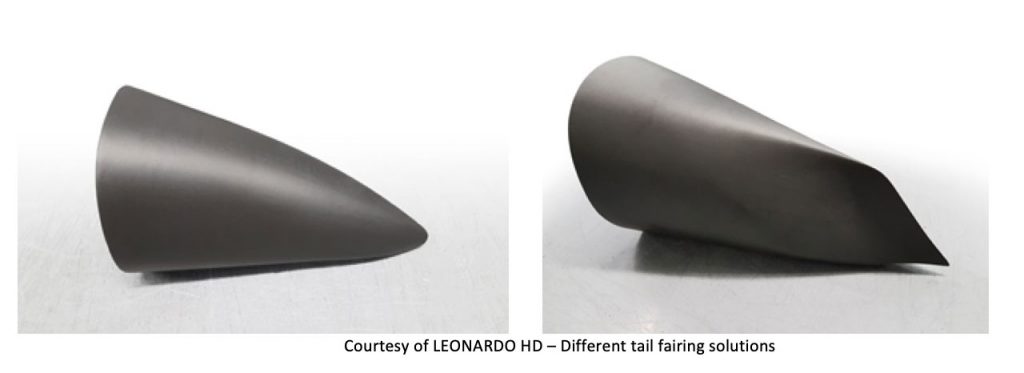

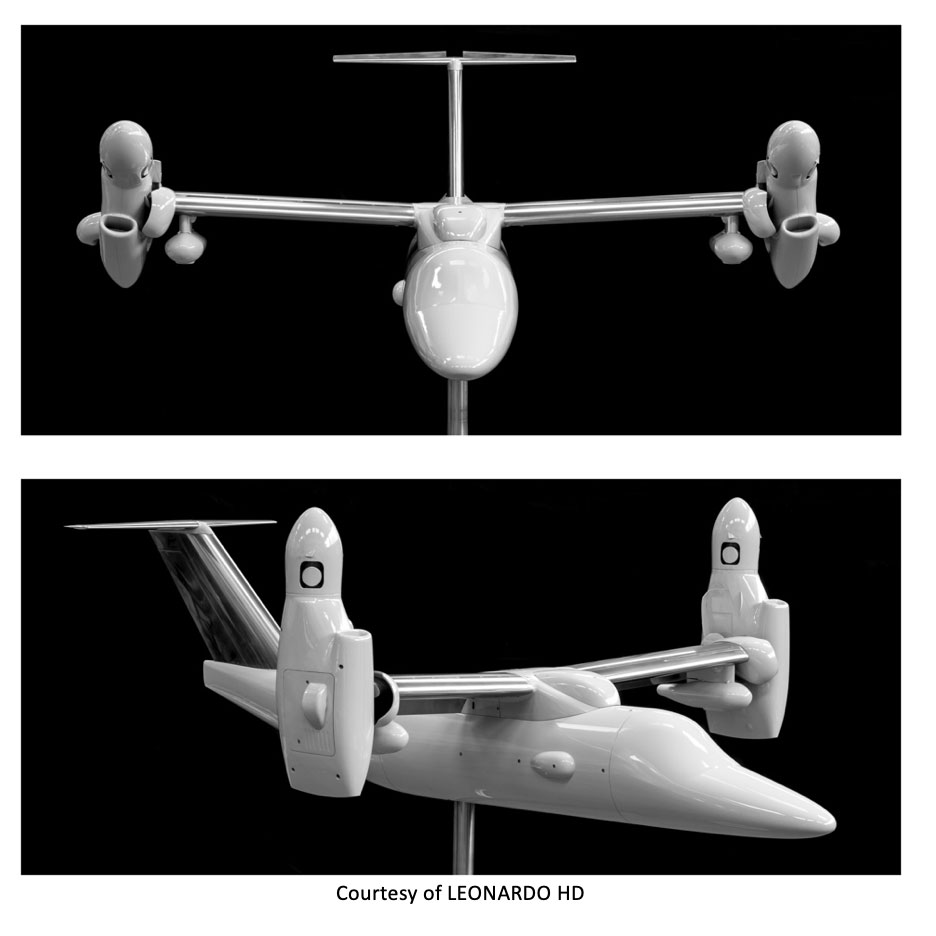

The project related to the manufacturing of some external parts (nose and cockpit, rear fuselage, nacelles, external fuel tanks, fairings) of the wind tunnel model (1:8.5 scale) for the prototype of the new LEONARDO HD tiltrotor AW609, made by Selective Laser Sintering technology and Windform® XT 2.0 Carbon-composite material, both supplied by CRP Technology.

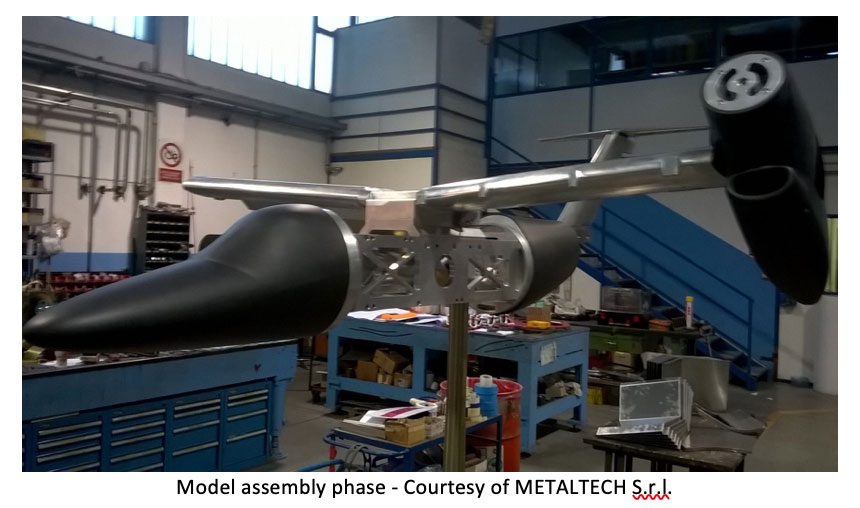

This wind tunnel model was designed, manufactured and assembled under the supervision of Leonardo Helicopter Division by Metaltech S.r.l. for a series of dedicated low speed wind tunnel tests.

The low speed wind tunnel tests were intended to cover a standard range of flight attitudes to be performed at Leonardo HD wind tunnel facility and at Politecnico of Milan for the high angles of flight envelope. During the different test sessions various external geometries have been changed and checked in order to understand all the aerodynamic phenomena.

The external main components redesigned and manufactured include: fuselage and nose components, fairings, nacelles and spinner shapes, empennage, wings and flaperons.

Goals

Leonardo Helicopter Division’s main goals, and therefore the reasons why they have been referring to CRP Technology, have been essentially the following two aspects:

– The requirement of a very short timetable, but with the highest level of reliability and commonality, in order to manufacture the external parts for the wind tunnel model;

– The research of materials with high mechanical and aerodynamic characteristics for these components that usually would have been made by a classical composite material

– To design and manufacture an aluminium alloy internal main structure suitable to be easily implemented with new geometries for the future aircraft versions or improved solutions.

This detail is crucial to the applied loads to be sustainable, and therefore they can’t be underestimated. In fact, the aerodynamic loads by the wind in the tunnel are very high.

The most critical aspect of the project is therefore the resistance to the loads, but also the necessity to maintain good dimensional tolerances of such a large dimensioned component under load. It is important that the components of the external fairings don’t deflect too much under load.

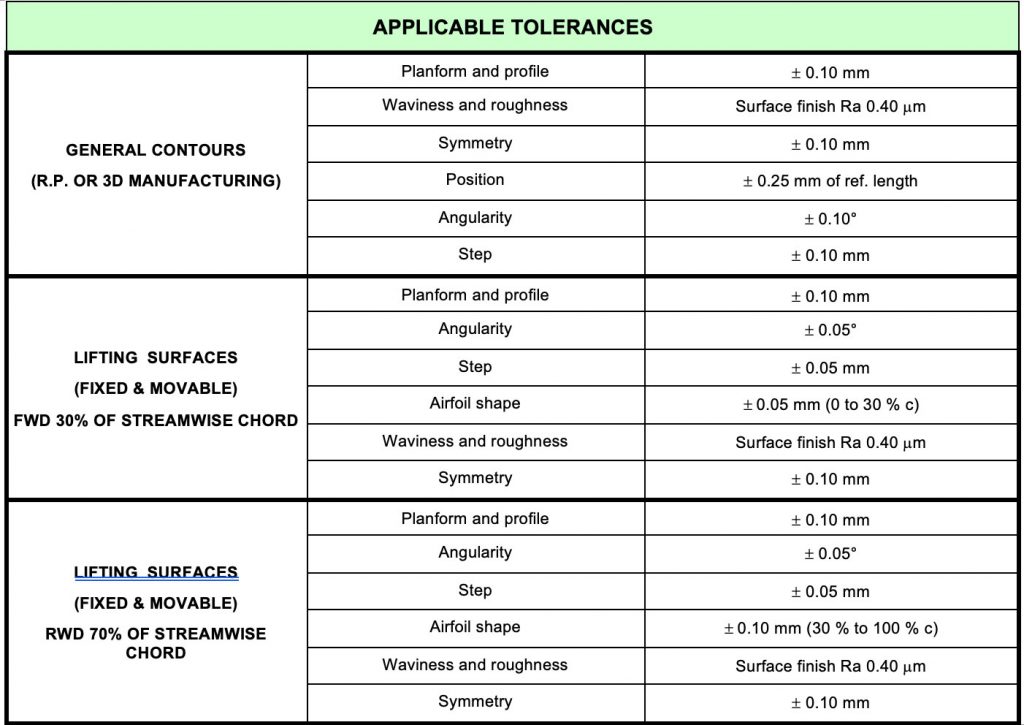

In addition, even when there are no external loads, the product must have dimensional characteristics in respect of the supplied specifications.

It is important to remember that the performance of these components affects the final performance of the entire project, especially because the external fairings have to transfer the aerodynamic loads generated by the fuselage to the internal frame.

Design condition

To assure the model capacity to withstand the loads expected during the various wind tunnel testing phases, stress and strain calculation have been performed. Such structural strength assessments have been executed for all the critical model components and for the assigned loading conditions.

The envelope of the expected model load conditions, obtained by scaling the full scale reference values, is fundamental to enable the requested structural evaluation and allow for a model components final design capable to guarantee the model full compatibility with both wind tunnel constraints (e.g. supports) and equipment (e.g. internal/external balances).

Model components materials and related stress limitations, stress concentrations, fatigue, etc. have discussed during the design phase.

The table below shows the tolerances required for the realization of a typical subsonic and transonic model for wind tunnel tests:

Model manufacturing technique

Wind tunnel model manufacturing technique has been changed during the years: historically such components would have been made by a classical composite material technology. The restrictions of this technology were generally the quite long manufacturing time.

Leonardo HD first wind tunnel model were manufactured using woods and metallic components and then change to a mixed solution of wood and composite fiber materials.

Nowadays all models are manufactured using CAD-CAM approach; an internal structural aluminum & steel frame is milled and assembled and all the external geometries are obtained through 3D printing techniques.

Advanced 3D printing combined to the Windform® XT 2.0 material has instead immediately convinced Leonardo HD, thanks to its very short manufacturing time and high-performance features.

Process and result

The activity of CRP Technology was based from the beginning on the maximisation and achievement of the requested goals.

The work started from a careful analysis of the dimensional designs received from Leonardo HD.

Thanks to the wide ranging experience of CRP Technology in this market, and thanks to the detailed knowledge of the materials and the technology, it was possible to assist the client in the choice of the best composite materials.

The choice of the Windform® XT 2.0 composite material was not casual, all the goals required by Leonardo HD were considered, such as the importance of a short realization time, good mechanical performances and also good dimensional characteristics.

Windform® XT 2.0 is a ground breaking carbon fibre reinforced composite 3D printing material known for its mechanical properties, appreciable for many applications such as wind tunnel, because of its high heat deflection (HDT = 173.40 °C; test method= ISO 75-2 TYPE A), superior stiffness, first-rate detail reproduction.

It replaces the previous formula of Windform® XT in the Windform® family of composite materials: Windform® XT 2.0 features improvements in mechanical properties including +8% increase in tensile strength, +22% in tensile modulus, and a +46% increase in elongation at break.

The first issue concerned the dimensions of the prototype: since some components were dimensionally superior to the construction volume of the 3D printing machines, it was necessary to manufacture separately the single parts. The long experience and deep knowledge of this process by CRP Technology’s staff have allowed the analysis, the study and the consequent perfect creation of such a complex project without any delay or problem for the client.

From the beginning the work was focused on the design of the components, with a correct split of the parts, considering of course the working conditions and the stress that the components would have to sustain.

Identifying the parts to split was an operation undertaken with the CAD, evaluating the functional measures of the working volume but also the possibility to optimize such volume and minimize the production time and costs.

The CAD cut was done with a special technique in order to maximize the contact surface in the place where the structural adhesive would be applied, thus having, also for very big parts but with relatively thin thickness, a great resistance to any kind of stress.

Therefore the unique technical characteristics of Windform® XT 2.0 remained absolutely intact.

The manufacturing time of the single parts was really short: not much more than one day was necessary to manufacture the jobs to set on the 3D printing machines and, after only 4 manufacturing days, all the various parts of the components were already physically created.

Different confidential efficiencies, which are an integral part of CRP Technology’s specific know-how, allowed the reduction of the delivery lead time and allowed CRP to minimize the normal tolerances of this technology, and eradicate any potential problem of deformation or out of tolerance.

The final step was the complete model surface finishing, directly mounted on the rig assembly in order to optimize the small imperfections that could have come from the union of the single components. In this case, too, CRP’s know-how -that has to be maintained confidential- allowed to execute this step in a very short time: it was therefore enough to flatten the surface of the whole model in an efficient way and treat it with a special liquid that has the double function to make it waterproof and prepare the surface to be painted without any problem.

All the model parts were then mounted and adapted to the main model structure thanks to a dedicated rig and assembled by Metaltech S.r.l.

The final result, in line with the timetable and characteristics of the part, has been finally tested in the LEONARDO HD wind tunnel facility at Bresso (Mi).

New 1:6 model for NASA AMES Unitary Plant 11’ by 11’ transonic high speed tests

As part of a thorough review of the aircraft behavior, Leonardo Helicopter Division has performed a high speed wind tunnel test campaign at NASA Ames Unitary Plan 11 by 11 foot transonic wind tunnel.

After a thorough assessment, the NASA AMES Unitary Plant 11’ by 11’ Transonic Wind Tunnel has been selected to obtain an accurate characterization of the aircraft in full scale conditions up to the highest speeds. The facility is pressurized transonic wind tunnel able to achieve full scale Mach numbers and Reynolds numbers close to full scale.

In order to speed up the manufacturing process also for this model, the external fuselage and additional components were manufactured using the same approach chosen for the low speed AW609 model: Selective Laser Sintering technology and Windform® XT 2.0 Carbon-composite material.

The parts were manufactured by CRP USA, CRP’s partner which is based in USA (Mooresville, North Carolina) under the control of the model supplier ATI Co. – Newport News (VA)

CRP USA demonstrated how the use of Windform® composite materials, originally developed for the motorsports industry by CRP Technology, is now finding many uses in space and aerospace exploration.

CRP USA also demonstrate the effectiveness of additive manufacturing and use of Windform® as a structural material for space applications: for the first time the Windform® XT 2.0 was used for an high speed model tested at NASA AMES facility.

The architecture of the new 1:6 model for transonic high speed tests is very similar to the AW609 model but with some improvements in order to have the remote controls for the flaperons and elevator surfaces.

Moreover the use of four different 6-components strain gauges balances allowed the acquisition of all the loads acting on the complete model, the wing alone, the nacelle and the tail surfaces.

The model scale selected were 1:6 of the full scale in order to be fully compatible within the given constraints of the physical size of the NASA 11 by 11 tunnel.

The model span was in the range of almost 2 m. The model were constructed to allow for mounting in the NASA 11 by 11 transonic tunnel, on a single strut straight sting support system.

This testing encompassed speeds between Mach 0.2 to Mach 0.6 with high Reynolds numbers and a wide range of angle of attach and side slip.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.