Windform® has passed the flammability UL 94 HB test and did not show degradation with VUV testing

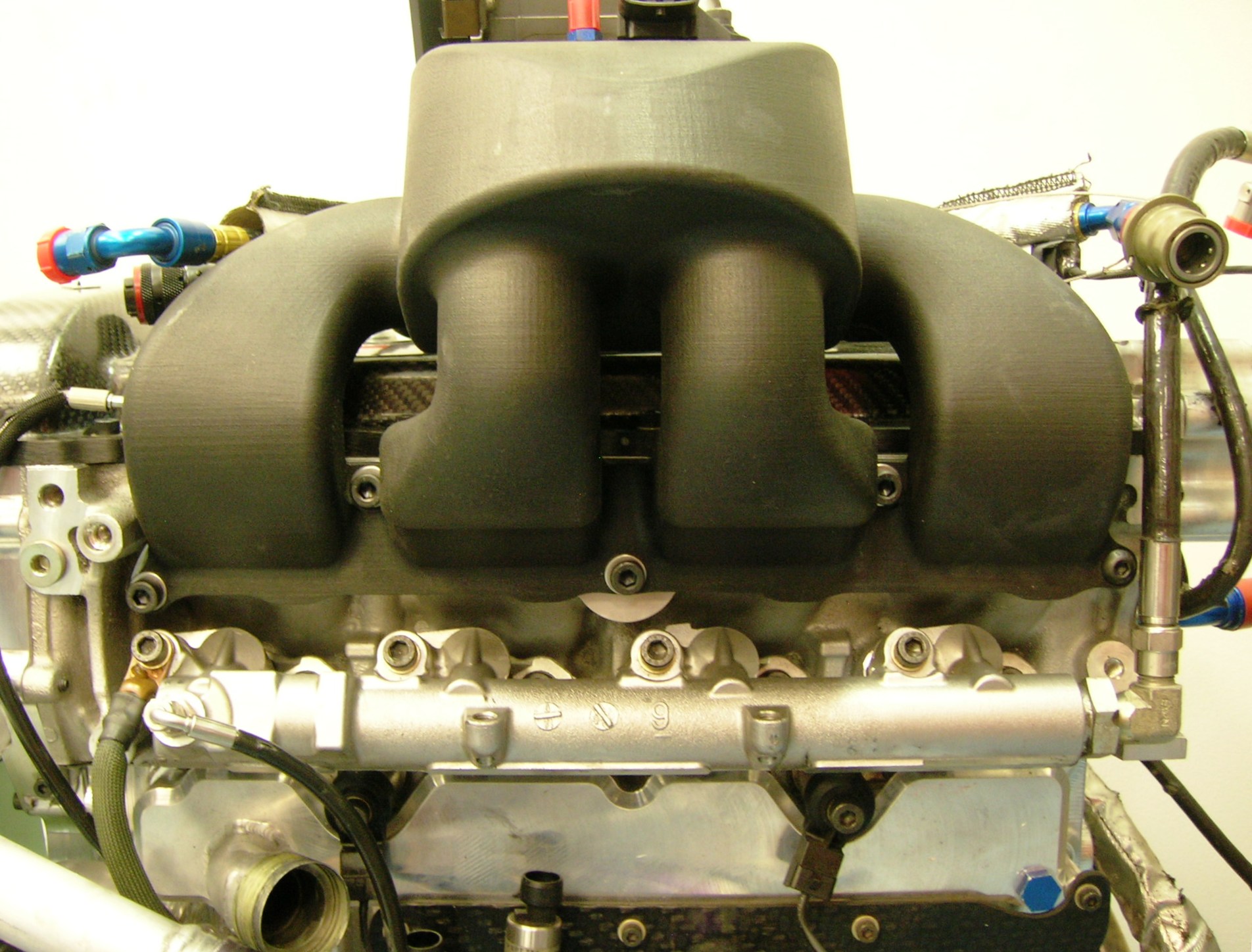

Windform® family of high performance composite materials by CRP Technology are unique in the field of Additive Manufacturing: the excellent thermal and mechanical properties make them the most suitable Laser Sintering materials to meet the demands of the most competitive and advanced sectors.

Windform® composite materials guarantee high standards of flexibility, elasticity, resistance (to damage from vibration, deformation, high and low temperatures, and liquids), and have been rated HB according to the flammability UL 94 test.

They were also exposed to vacuum ultraviolet radiation and did not show degradation.

Laser Sintering polyamide-based carbon fiber reinforced Windform® XT 2.0 and Windform® SP composite materials, along with LS polyamide-based glass-fiber reinforced Windform® GT and Windform® LX 3.0 composite materials, have been tested for their flammability rating.

Laser Sintering polyamide-based carbon fiber reinforced Windform® XT 2.0 and Windform® SP composite materials, along with LS polyamide-based glass-fiber reinforced Windform® GT and Windform® LX 3.0 composite materials, have been tested for their flammability rating.

The “Test for flammability of plastic materials for parts in devices and appliances” UL 94 was carried out on test specimens 1 to 3 mm thickness.

The result of the flammability UL 94 HB test reports Windform® XT 2.0, Windform® SP, Windform® GT and Windform® LX 3.0 have successfully obtained the HB classification.

Samples of Windform® LX 3.0 and Windform® SP were subjected to VUV testing by exposing to ~8 solar equivalents in LEO, with a wavelength range of 115-200 nm VUV radiation from a 30 W Hamamatsu L7292 deuterium lamp for 36 continuous hours.

Test results report “Windform® SP and Windform® LX 3.0 samples did not show degradation with VUV testing”.

Both test results confirm Windform are the most appropriate composite materials for challenging and harsh applications.

Results can be obtained from the website here.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.