KD-1 is the first 3D printed driver head made from Windform high performance 3D printing materials with precision CNC machined Titanium striking face. Manufactured by CRP Technology (CRP Group’s 3D printing specialized division) and CRP Meccanica (CRP Group’s CNC machining company). This performance driver golf club has been co-engineered by CRP Group and Krone Golf on behalf of Krone, the world leader in custom engineered golfing equipment.

KD-1 has been shortlisted for the Consumer Application category for the TCT Awards 2017.

The winner will be announced on September 27th at the inaugural TCT Awards during the three days of 2017 edition of the TCT Show.

The event will be held at the prestigious Birmingham Town Hall, Birmingham, UK.

“We are very pleased to have been selected for the TCT Consumer Product Application Award 2017 – states Franco Cevolini, CRP Group CEO – . KD-1 is a precise example of the “CRP Method”, which allows the customer to rely entirely on us from the design phase to the delivery of the finished product. For over 45 years we have been working for the F1 world with CRP Meccanica, the CRP Group’s specialized division in precision CNC Machining, and for over 20 years we have been working in professional 3D printing field with our Windform family of reinforced materials through CRP Technology. Companies working in the F1 field have something different in their DNA: you have to work harder, faster and provide excellent service. But above all, you have to foresee customers’ needs and offer them the right solution”.

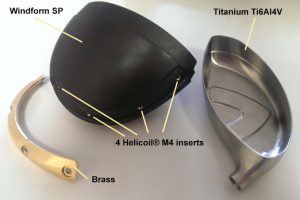

The KD-1 body structure has been manufactured by CRP Technology’s 3D Printing and Additive Manufacturing department utilizing Laser Sintering and the innovative Windform SP Additive Manufacturing material. Windform SP is a highly ductile material with excellent mechanical properties.

The body has 4 Helicoil® M4 inserts at the end to fasten its weight.

The KD-1 face (the striking surface of the head of the club) is made in Ti6AI4V: it has been CNC machined from solid billet and sand blasted to clean external surfaces by CRP Meccanica; the housing was also produced in Titanium as well. The weight is also CNC machined from solid brass and sand blasted by CRP Meccanica.

The combination of 3D printing and CNC machining leads to increased speed of manufacturing process’, and time saved. Additive manufacturing technology is much faster than designing and producing tools for injection molding. Furthermore, 3D Printing can give engineers more flexibility to make design improvements and quick changes.

Additive and Subtractive processes, along with the use of Windform 3D printing, have also improved the speed, precision, design, flexibility and part optimization for our customers.

The K D-1 has been swung over 2,500 times, proving its strength and durability.

The TCT Awards will be a formal evening recognizing and celebrating the most innovative products, technologies and individuals in the 3DP & AM industry. With 10 award categories decided by a judging panel of AM experts and industry peers, the TCT Awards will be the most prestigious and sought-after accolades in the fastest-growing and most exciting sector of engineering.

Duncan Wood, COO, Rapid News Publications Ltd, owners of TCT, explains the thinking behind the awards categories: “Many technology awards have categories for almost all types of machines, in the end it can come down to which company pressures its users to vote for them. However, it’s not how we wanted to do things. Ultimately, technology is made great by the innovation and skills of those who use it. So, we will reward the best applications of 3D manufacturing technology in multiple areas, we feel this is a true reflection of the impact of the technologies on our world.”

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.