Global market leader in turbochargers replaces casting with industrial 3D printing, reducing lead times for parts with weeks

After an extensive market survey and process evaluation, ABB Turbocharging, a technology and market leader in the manufacture and maintenance of high-end turbochargers, has decided to invest in Additive Industries’ MetalFAB1 platform. With this state-of-the-art metal additive manufacturing system, designed for industrial production, ABB produces spare parts for its 500 kW to 80+ MW turbochargers for diesel and gas engines on-demand. ABB and Additive Industries are jointly optimizing the integrated process to replace casting and move part fabrication to the digital space. ABB has over 200.000 turbochargers in its installed base in the marine engine and emergency power generation business. To secure availability for the thousands of different turbocharger spare part designs with casting lead times up to nine weeks, a large number of spare parts need to be carried in inventory. With the MetalFAB1 platform, the spare parts manufacturing lead times can be reduced to a week, so spare parts inventory levels can be reduced significantly.

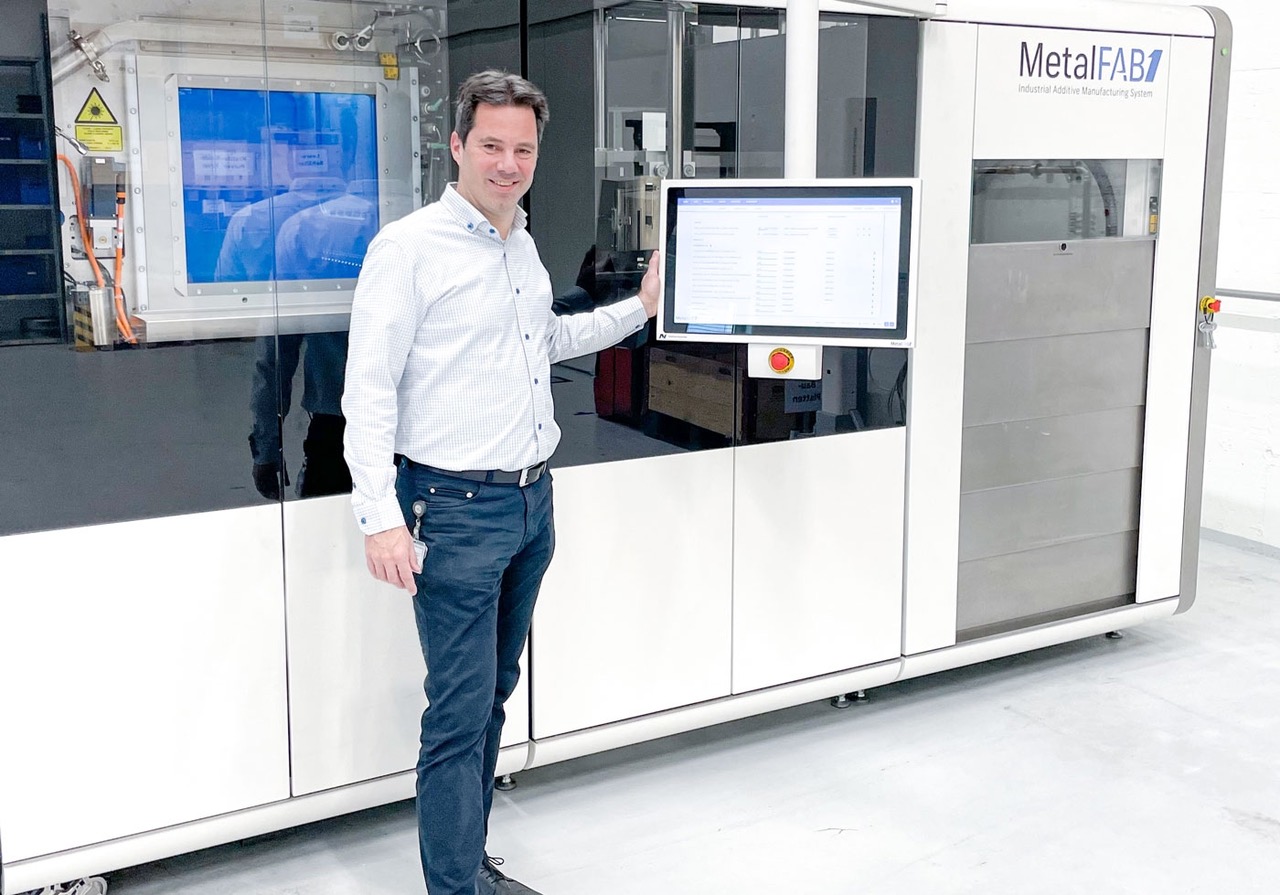

‘In Additive Industries we have found a partner that not only understands what is required to use 3D metal printing in an industrial environment, but they also share our passion for digital technologies to continuously improve the service to our customers’, said Egon Seegers, General Manager Service Parts of ABB Switzerland Ltd, Turbocharging.

‘With ABB we have added another market leader to our very focused list of customers. They are committed to drive progress in the domain of digital spare part manufacturing, very relevant in a time where shortening the lead times and limiting logistical movements around the world is key’, added Ian Howe, CEO of Additive Industries.

‘ABB services over 200.000 turbochargers around the globe on ships, in power stations, generatorsets, diesel locomotives and large, off-highway vehicles. The potential for on-demand 3D printing of spare parts is immense’, concluded Mark Massey, Additive Industries’ CCO. ‘We are very happy to be able to support ABB in further improving customer service and satisfaction by greatly optimizing the manufacturing process of parts for turbochargers.’

More information: www.additiveindustries.com

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.