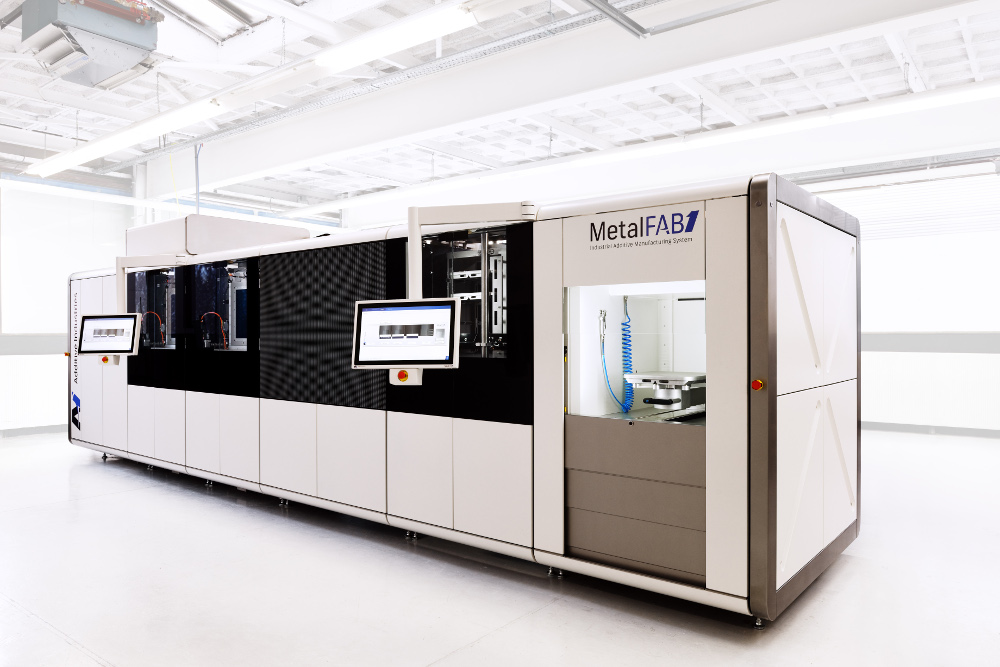

Following the announcement of the closure of its beta programme, Additive Industries has delivered the first MetalFAB1 3D printer to Airbus Group subsidiary APWorks. Among the other beta testers are the Kaak Group and United Grinding Group.

APWorks will start testing the system including its Additive World software for series production of industrial parts. The company’s customers range from the fields of robotics, mechanical engineering and automotive to medical technology and aerospace. Being part of the beta programme, APWorks will evaluate the processes and applications for multiple materials simultaneously to officially validate and certify the process for the most critical parts.

“Today we are taking an important leap forward in industrialising metal additive manufacturing technology. This will substantially improve part reproducibility and reduce the total cost of 3D printed parts,” said Joachim Zettler, Managing Director of APWorks.

Daan Kersten, co-founder and CEO of Additive Industries adds: “For Additive Industries this 1st shipment is an important milestone. Following the smooth installation and successful completion of the site acceptance tests at APWorks, we can now start our beta test phase as a preliminary step to ramping up for series production of the MetalFAB1 system.”

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.