As work on Sighthill Bridge across the M8 in Glasgow nears completion, BAM has become the first contractor in Scotland to make use of 3D concrete printing – installing the staircase which will provide access to the new structure. It is believed to be largest printed concrete construction in the UK to date.

When complete, the iconic new pedestrian and cycle bridge will connect Glasgow City Centre to the Sighthill area in a new sustainable transport corridor.

Working on behalf of Glasgow City Council, BAM craned in the new staircase this week. Once fully installed the new steps will be clad in granite, creating attractive, long-lasting, slip-free finish.

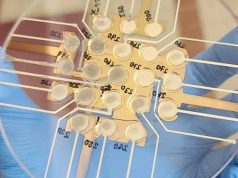

Printing the bridge components allows for precise and intricate shapes, which can be tricky with traditional formwork, creating a truly unique structure. The removal of moulds and materials reduces waste by 40% compared to traditional methods, keeping costs down and improving carbon efficiency.

The staircase will be just as strong as if poured on site, however, this innovative method allows the structure to be manufactured in a highly controlled environment, removing concerns around weather and reducing the risks associate with on-site construction. Automated sensors embedded in the materials add further certainty to the quality of mortar throughout the process.

The steps were printed by Weber Bemix in their factory in the Netherlands before being shipped to Scotland. BAM has a sustained relationship with the concrete printing experts, previously creating the world’s longest 3D concrete printed bridge with them in 2019 in Nijmegen, Netherlands.

Ian Steele, BAM Contracts Manager for the M8 Footbridge said: “It’s wonderful to see these 3D Concrete printed aspects installed as this iconic bridge takes shape. The printed element saw us manufacture the stairwells offsite, creating strong, one-of-a-kind structures, all while reducing waste and interaction with weather and other elements which can create hold ups.

Although this part of the landscaping will ultimately be hidden from site, it marks a huge step forward for BAM in how we modernise our approach to construction – reducing risk, improving efficiency, and driving down our carbon footprint.

The use of this technology is in its infancy, but the aspiration is that interest and application grow to such a degree that we can invest in a UK based printing facility which would improve how we construct within the UK”.

Find out more about BAM at bamnuttall.co.uk.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.