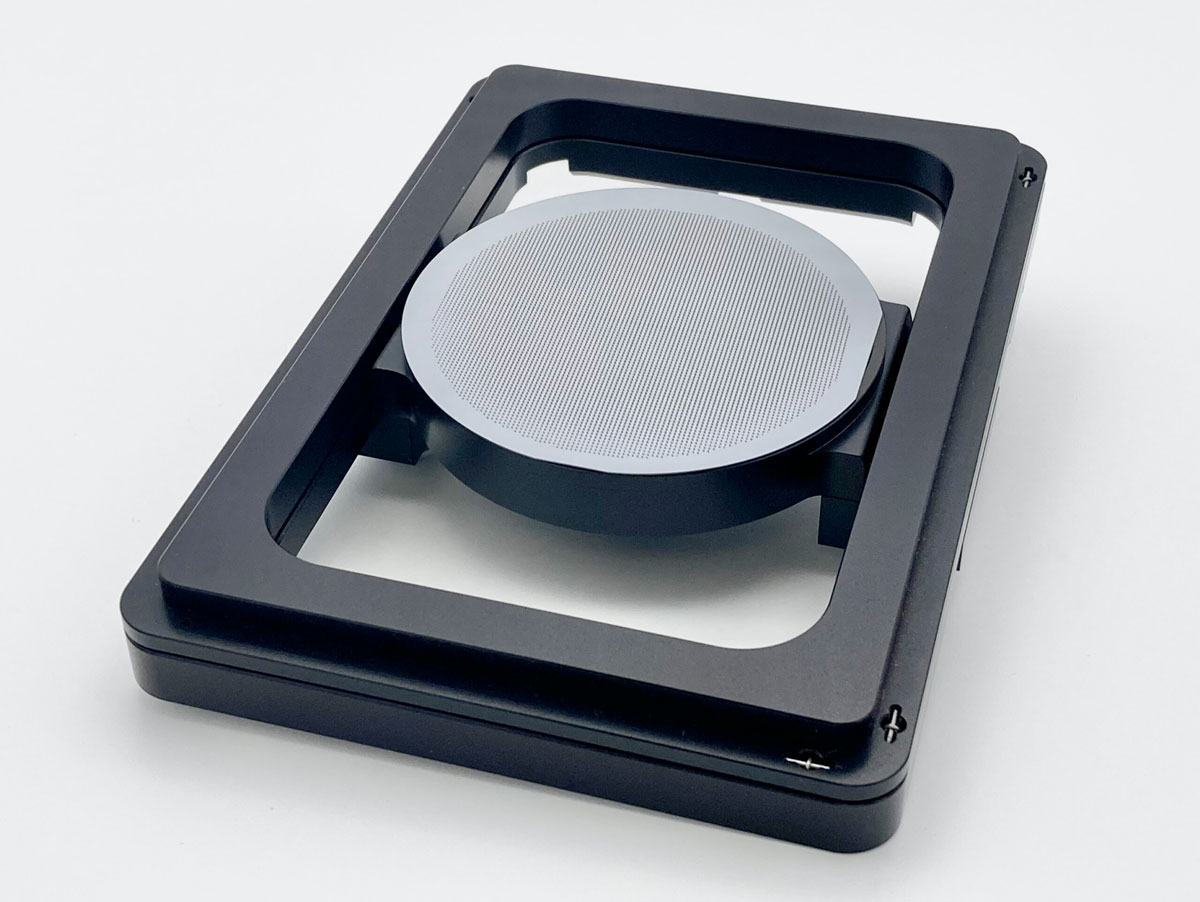

A novel device allows the compensation of miniscule unevenness in 2PP 3D-printing substrates whilst printing. The so-called Tilt Frame has now been introduced internationally by the market’s innovation specialist UpNano GmbH (Austria).

The frame can be fitted with chuck-holders for industrial standard wafers between 2 to 6-inches. In this way 2PP 3D-printing over entire surfaces of wafers up to 4-inches has become reality. The Tilt Frame (retro-)fits any of the renown NanoOne series of laser-powered 2PP 3D-printing systems by UpNano that can build structures across 12 orders of magnitude at an unprecedented speed.

Being able to print structures at nanometer resolution as well as in the centimeter dimension, the NanoOne series is unparalleled on the market of laser-powered 2PP 3D-printers. It has already been used in electronics as well as in microoptics and for biocompatible applications in cell and medical research.

But whatever the application, in 2PP 3D-printing size matters after all: the large-scale the printed structure, the more the slightest unevenness of the print material will affect the precision of the final product. This well-known complication has now been addressed and solved by UpNano GmbH. The R&D department of the company with premises in the USA and Austria developed a tiltable frame that can correct an unevenness in the µm-range. The Tilt Frame can be extended with various holders, including a series of chuck-holders for up to 6-inch wafers. Even more importantly, the entire surface of wafers up to 4-inch is now accessible for 2PP 3D-printing. A world-wide first in the industry.

Maximum Precision

“By equipping any NanoOne printer with the Tilt Frame”, explains Denise Hirner, Head of Marketing and Business Development and co-founder of UpNano, “one maximizes the precision of the print result especially of large-scale structures.”

The handy frame can be ordered separately for easy fitting to an existing NanoOne printer or as a pre-installed accessory to any new NanoOne.

The frame allows correction of substrate differences in the µm-range. Correction values are obtained by the NanoOne autofocus that takes height measurements at three points of the substrate. Based on these measurements, correction values are calculated. For the actual adjustment there are two versions of the Tilt Frame available. A competitively priced manual version that uses highly precise correction screws or an automatic version which uses software controlled precision motors for correction. The frame is compatible with all optics available for the NanoOne Series, namely the 5x, 10x, 20x and 40x objectives.

Full Circle

Whilst mounted on the NanoOne-standard long-range piezo stage with 120x100x40mm travel range, the Tilt Frame allows printing “over the largest possible print area of any 2PP 3D-printer on the market”. In fact, using the additionally available chuck-holders, this area allows for the first time 2PP 3D-printing on the entire surface of industry standard 2-, 3-, or 4-inch wafer. Even on 6-inch wafers an area of 50×70 mm is available for printing.

Denise Hirner comments: “The NanoOne can print at a staggering writing speed of up to 1,000 mm/s and achieves a throughput of up to 200 mm³/h. This plus the newly achieved ability to print the entire surface of an industry standard wafer of up to 4-inch makes series production with 2PP 3D-precision for the first time feasible.”

But the chuck-holders are not the only accessory that make the Tilt Frame even more interesting. UpNano also added a fibre-holder as well as a ferrule-holder to the portfolio. By using these holders together with a printing material with optical properties from the UpNano portfolio that has been optimized for the process, integrated optical systems can be positioned and manufactured with high precision on the tip of an optical fiber.

For more information, please visit www.upnano.at.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.