Formnext 2023 is just around the corner and Horizon Microtechnologies is gearing up for the prestigious show. The company is partnering with Boston Micro Fabrication (BMF), a pioneer in micro-AM, at booth B38 in Hall 11.1, where Horizon will exhibit micro-AM components that impress with their innovative, non-metallic, conductive and environmentally resistant coatings.

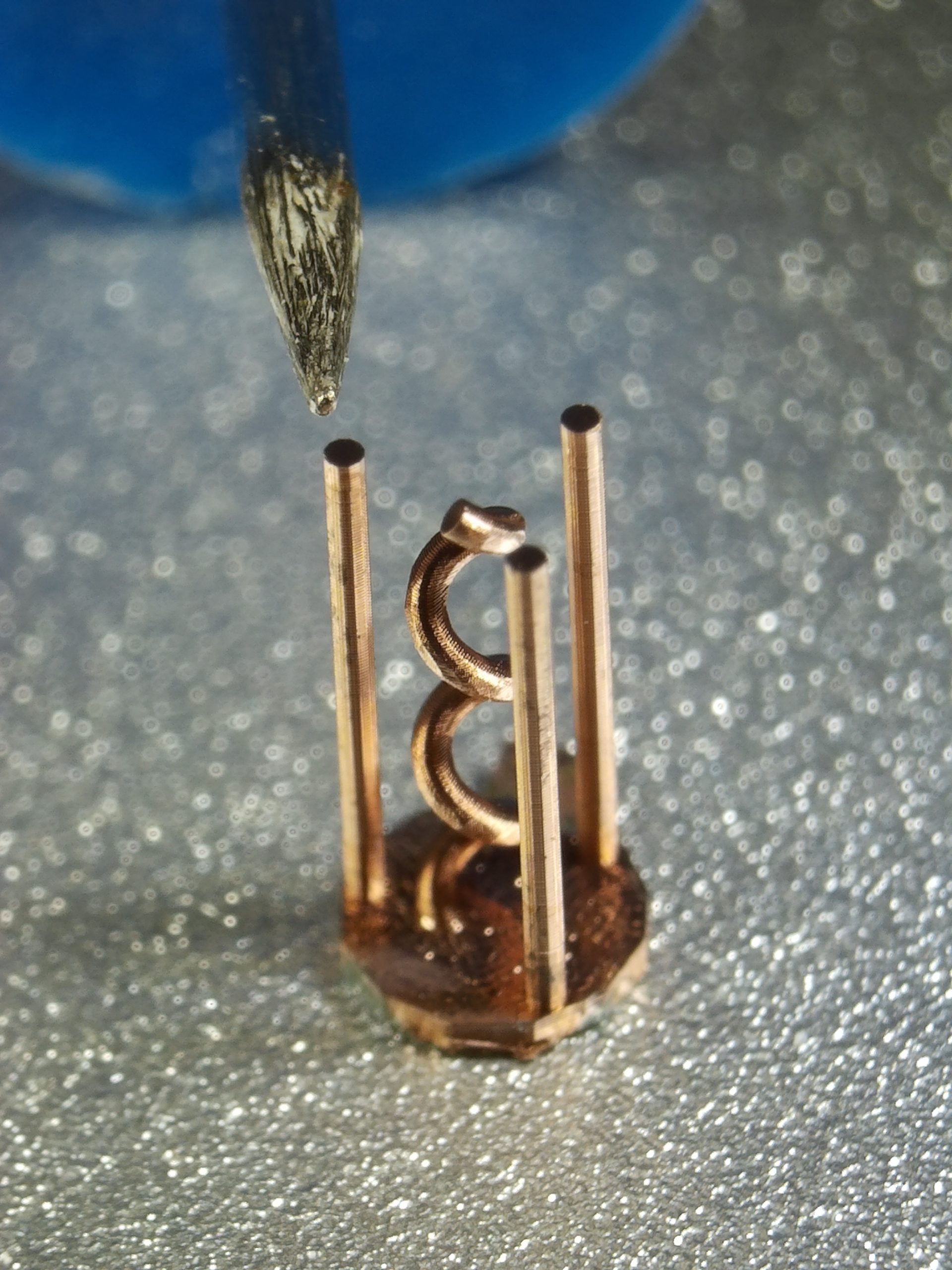

These special coatings significantly expand the application possibilities of micro-AM. They are particularly suitable for electrodes, electrical connectors, 3D microfluidic devices, MEMs, optical packaging, and state-of-the-art mm-wave antennas and similar components. The environmentally resistant coating also increases the reliability of microdevices, especially in extreme environments such as contact with aggressive chemicals or high temperatures.

CEO at Horizon, Andreas Frölich says, “As Formnext gets closer, we are increasingly excited to engage with visitors after a hugely important year for our company which has seen us receive early-stage funding tailored for innovative tech start-ups. This has allowed us to bring the full technology infrastructure for our 3D microfabrication printing and coating processes in-house which has created enormous advantages for our customers who can access a truly vertically integrated solution partner that can support them from design through manufacturing to delivery in a one-stop-shop fashion.”

Horizon’s downstream coating technologies significantly improve 3D microstructures. Even though the templates often originate from polymer micro-AM processes, parts from different machining processes can be integrated into Horizon’s coating chain. This technology enables a combination of the advantages of polymer micro-AM and functional coatings.

Frölich continues, “Our in-house coating technologies can wholly or selectively coat micro-AM parts. By so doing, we effectively open up the resolution, tolerances, weight saving possibilities, geometric complexity, and other attractive features of polymer micro-AM for applications where it is otherwise not appropriate due to the polymer’s material properties. Our post process coating technology is unlike any other on the market, and allows us to offer unique possibilities when adding metal, non-metallic conductivity, or environmental resistance to micro-AM parts. We welcome the opportunity to discuss the possibilities this can open up for visitors at Formnext, and we value the opportunity to forge new relationships with customers to expand the use of AM into new application areas.”

Following a recent investment in the BMF S240 machine, a micro-AM device with extremely high precision, Horizon is now ideally positioned to support customers at various stages of product development.

Visitors to Formnext from November 7-10 are invited to visit Horizon and BMF in Hall 11.1, Booth B38, and experience the disruptive capabilities of micro-AM first-hand.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.