Boston Micro Fabrication (BMF), known for its precision micro 3D printing, has qualified Mechnano‘s Formula1µ resin for its S240 10-micron printers and newest 3D printer platform, the 25-micron microArch S350. This represents a significant step for 3D printing of microscale parts with high-resolution features.

What makes Formula1µ special is its ability to produce electrostatic dissipative (ESD) parts, especially for use in environments below 90°C. This opens up new opportunities for researchers and manufacturers to develop prototype and end-use parts with ESD properties.

“Our team is excited to announce this qualification,” said Mechnano President Bryce Keeler. “Formula1µ provides BMF customers with a high-performance resin—delivering the highest tensile strength option available on the BMF platform and the only resin that dissipates static electricity. With the dual increase of electronics usage and decrease in chip size, the applications requiring micro-ESD parts are growing daily.”

“We’re continuing to collaborate across the industry to expand the use of 3D printing from discrete, prototyping applications into a solution that drives highly precise production of parts across industries including electronics, medical devices, and the life sciences,” said BMF CEO John Kawola. “Thanks to Mechnano’s innovation, we’re now able to offer our customers another material option to support their prototyping and longer-term production needs.”

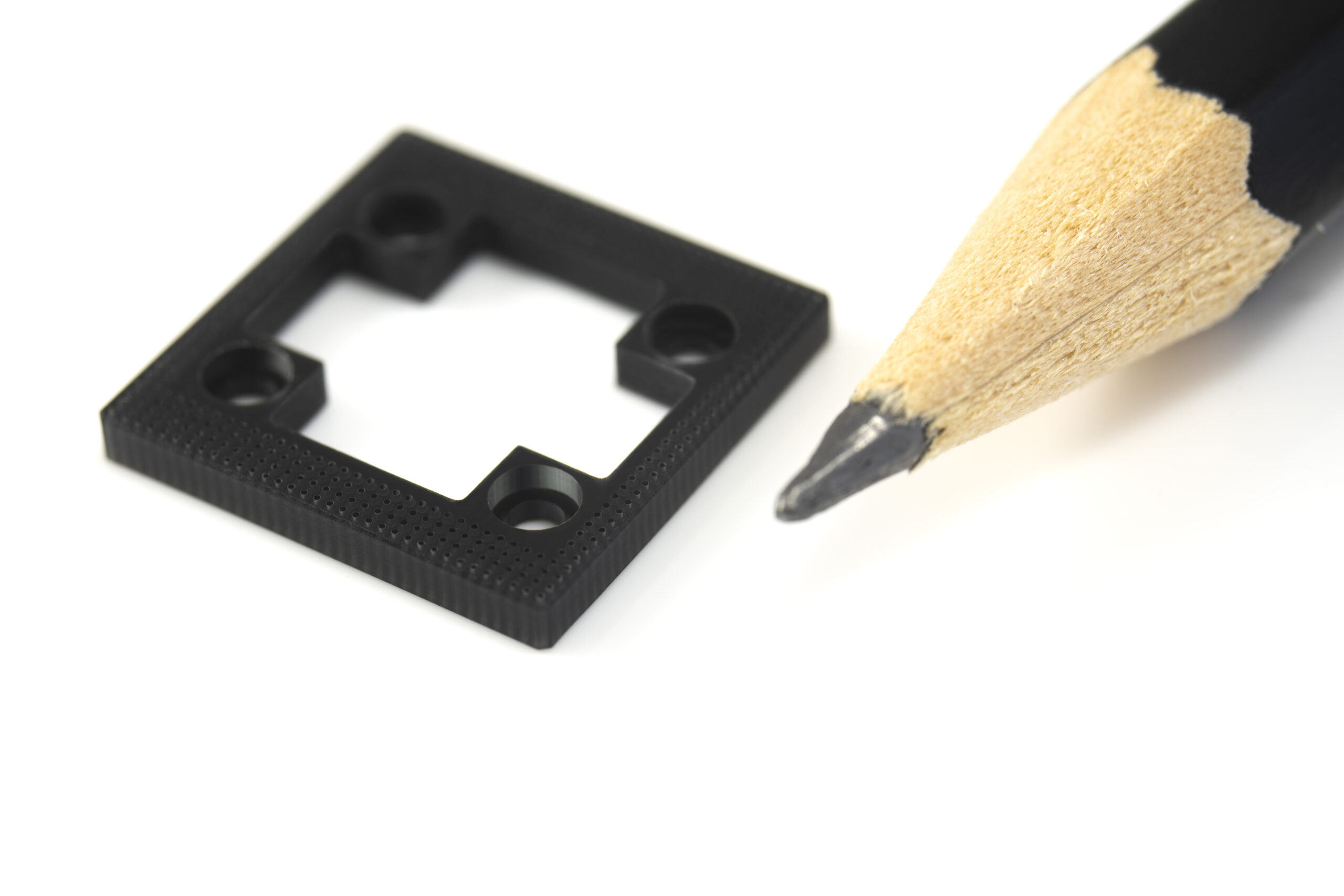

Mechnano’s Formula1µ resin is a black, rigid and static dissipative photopolymer resin. It was developed using Mechnano’s proprietary D’Func technology, a discrete carbon nanotube technology. This enables the production of high-resolution ESD parts with isotropic properties and no carbon delamination.

Taken together, this qualification illustrates the ongoing progress in the micro 3D printing sector and how partnerships between companies such as BMF and Mechnano are driving the sector forward and opening up new application opportunities.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.