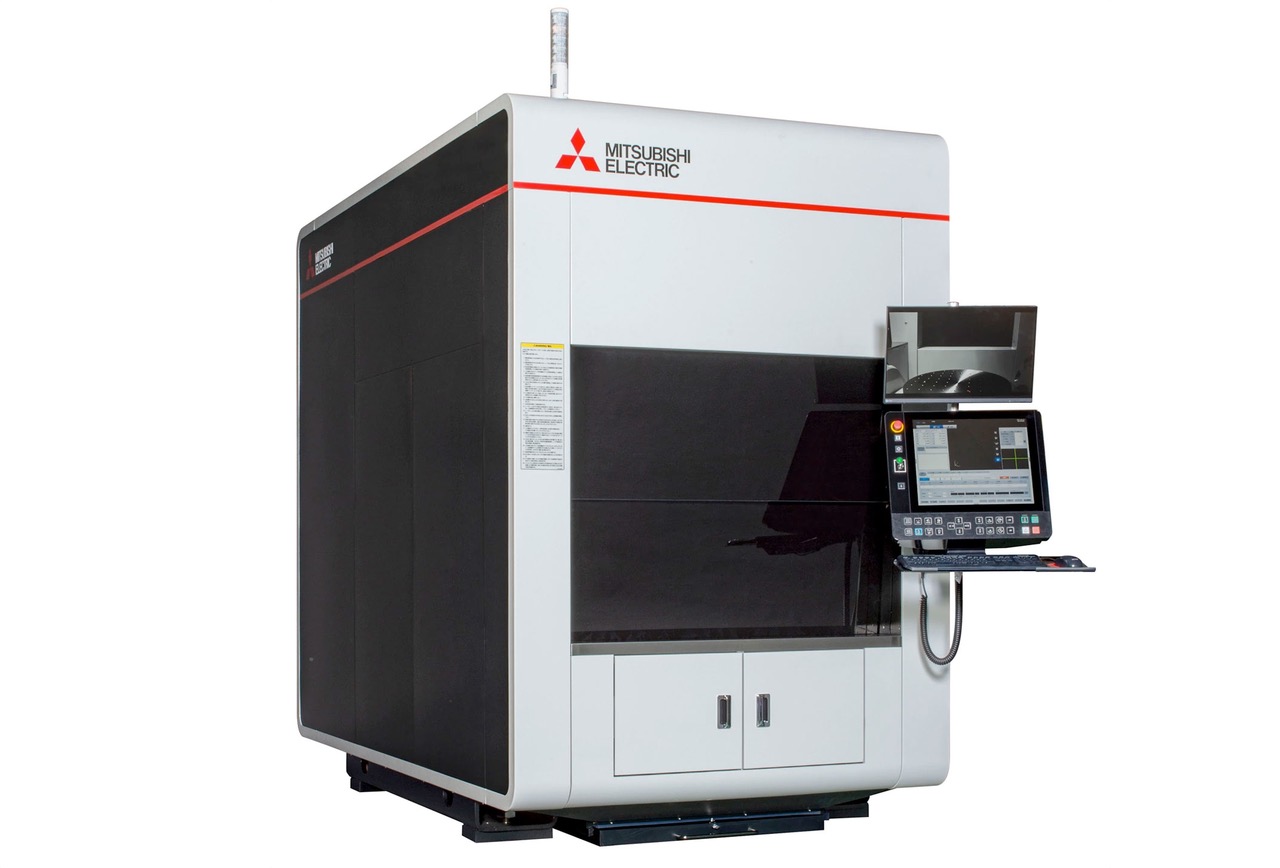

Mitsubishi Electric Corporation (TOKYO: 6503) announced today that on March 1 it will release two models of the “AZ600” wire-laser metal 3D printer, which melts welding wire with a laser beam to create high-quality 3D structures.

Digital additive-manufacturing technology combined with simultaneous 5-axis spatial control and coordinated control of machining conditions, a world’s first*, delivers stable, high-quality 3D printing. Furthermore, it contributes to manufacturing in a decarbonized era by reducing energy consumption, saving resources by shortening processing time and using highly efficient production methods such as ‘near-net-shape’, and supports the build-up of repairs for the maintenance of specialist parts for automobiles, ships and aircraft. Additionally, a new contract printing service utilizing these printers will help the adoption of additive manufacturing by offering product design consultation, prototyping and general advice about the application of 3D metal printing.

In recent years, the growing need to reduce CO2 emissions in the metalworking manufacturing industry has stimulated an increase in demand for more efficient metalworking methods that reduce energy consumption and conserve finite natural resources. In particular, demand is expected to grow for metal 3D printers, which create objects from 3D shape data. This has the advantages of significantly shortening the conventional manufacturing process, reducing waste materials in the manufacturing process, and improving design flexibility by making it easier to integrate multiple parts and reduce weight. On the other hand, metal 3D printers that use powder-based feedstock have issues with material management, workability and safety, and a new additive manufacturing process has been required. To solve the problems with powder-based printers, Mitsubishi Electric is now launching the AZ600, a world’s first* wire-laser metal 3D printer that combines simultaneous 5-axis spatial control and digital additive-manufacturing technology that precisely and cooperatively controls processing conditions. This product realizes high-quality, high-precision 3D printing and contributes to manufacturing that considers its environmental impact by reducing energy consumption and waste.

The “AZ600” will be exhibited at the “Additive Manufacturing Expo” from March 16-18 at Tokyo Big Sight. The Wire-laser metal 3D printer AZ600-F20 with 2kW and AZ600-F40 with 4kW is planned to be released on March 1 in a volume of 100 machines annually.

*As of February 24, 2022, according to Mitsubishi Electric’s research

Picture & Link: www.mitsubishielectric.com

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.