A team of researchers from the University of California San Diego and BASF Group have collaborated to develop a novel soft robotic gripper. The device, fully 3D-printed and without electronics, can be used immediately after the printing process.

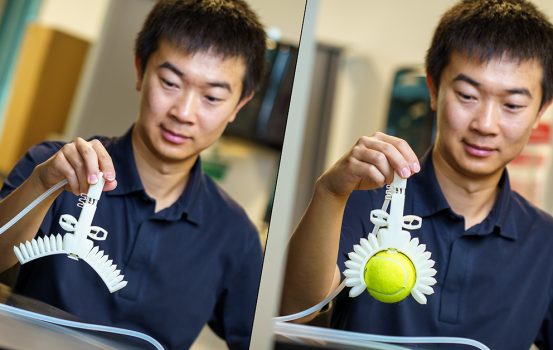

The team, led by Yichen Zhai, created a gripper with built-in gravity and touch sensors. These allow the gripper to pick up, hold and release objects.

“We designed functions so that a series of valves would allow the gripper to both grip on contact and release at the right time,” said Yichen Zhai, a postdoctoral researcher in the Bioinspired Robotics and Design Lab at the University of California San Diego and the leading author of the paper, which was published in the June 21 issue of Science Robotics. “It’s the first time such a gripper can both grip and release. All you have to do is turn the gripper horizontally. This triggers a change in the airflow in the valves, making the two fingers of the gripper release.”

Soft robotics offers the potential for safe interactions between robots and humans or delicate objects. This gripper could be used in industrial manufacturing applications, food production, or research and exploration.

One challenge the team faced was that 3D-printed soft robots often leak and require processing and assembly after printing. By developing a new 3D printing method, this problem was solved.

“It’s like drawing a picture without ever lifting the pencil off the page,” said Michael T. Tolley, the senior author on the paper and an associate professor in the UC San Diego Jacobs School of Engineering.

This method reduces the likelihood of leaks and defects and enables the printing of thin, complex shapes and walls.

“When we followed these rules, we were able to consistently print functional pneumatic soft robots with embedded control circuits,” said Tolley.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.