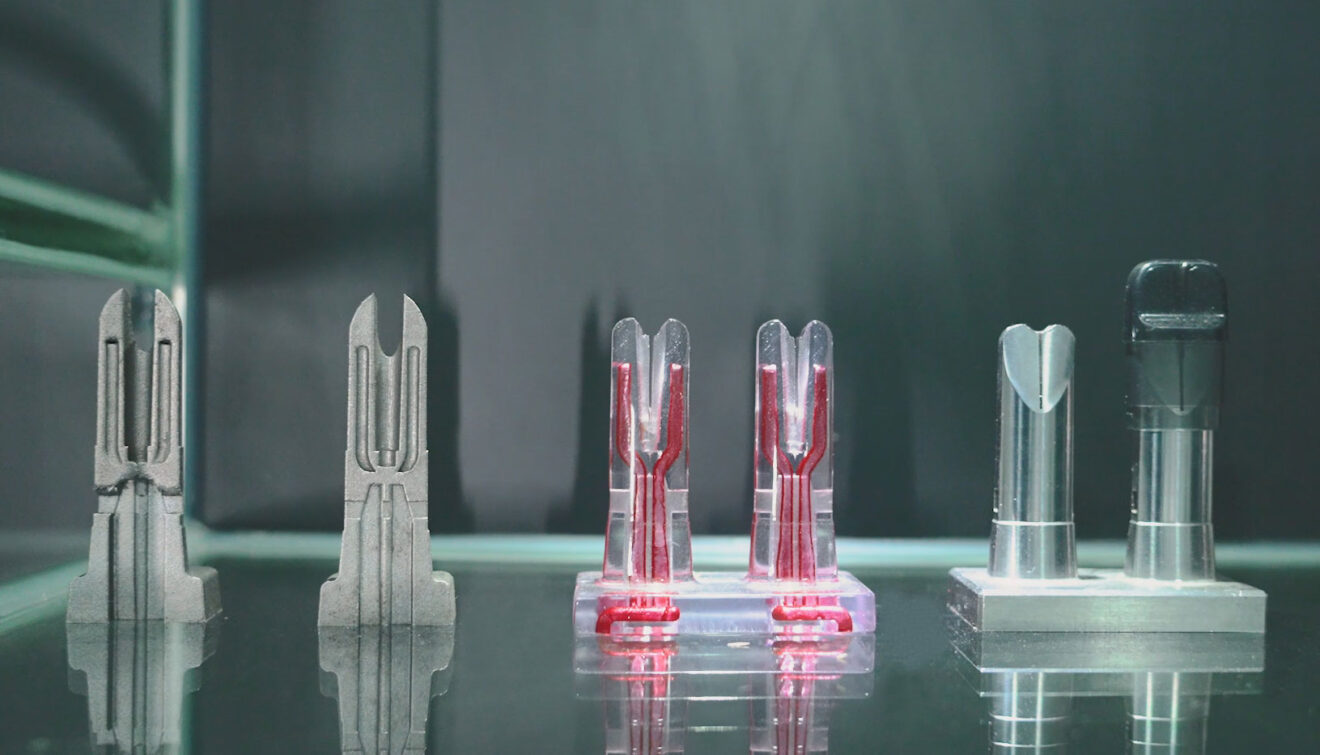

Chinese company Borton Precision produces customized injection molds for e-cigarettes using metal 3D printing from Farsoon. To reduce manufacturing costs, Borton developed a solution to automatically align 3D-printed and conventionally manufactured parts.

According to Borton Precision, this has reduced the manual process of positioning parts with millimeter accuracy from four hours to just four minutes. At the same time, accuracy was increased to less than 0.05 millimeters.

In a specific application example, automation led to 70 percent higher productivity and 69 percent lower material costs in the production of injection molds for e-cigarettes.

According to the example, manufacturing efficiency can thus be increased enormously by cleverly linking 3D printing and smart automation. Human error sources are reduced and the strengths of additive and subtractive processes are combined. Investments in automation technology can thus quickly pay off for manufacturing companies that use 3D printing.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.