3D printers have a unique way to serve the fashion industry today. It has been used by designers and engineers for nearly now 3 decades. These printers plays a very essential role in helping the professionals to make prototype parts required by the industries such as automotive, aerospace, fashion and defense companies. These are not the only industries that are benefited from the 3D technology. It is now become a mainstream in the fashion industry due to its versatile nature.

Just like any other industry, these printers in the fashion industry are not new, whether it is jewelry designing or fashion for cloths, the printer are used in numerous works. The professionals have been outsourcing from printing companies for years now, but for some reason this technology is gaining the attention of the public as well as the designers.

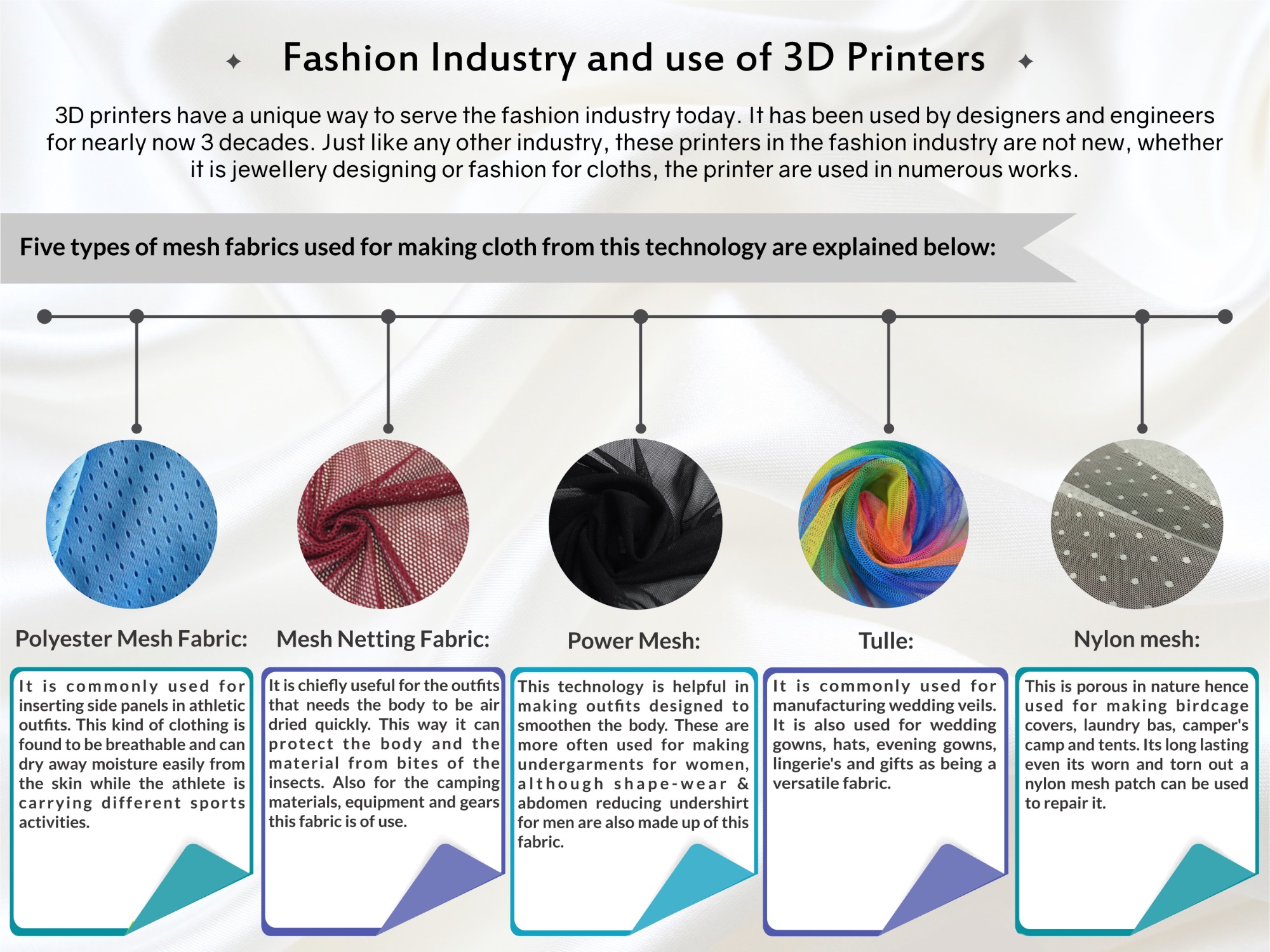

Five types of mesh fabrics used for making cloth from this technology are explained below:

Polyester mesh fabric:

It is commonly used for inserting side panels in athletic outfits. This kind of clothing is found to be breathable and can dry away moisture easily from the skin while the athlete is carrying different sports activities. This kind of fabric is also used by the clothing designers in the form cover to add dimension and texture to tricot and other flat weave materials. The delicate part of the body can be camouflaged by making use of two layers of this fabric of mesh.

Mesh netting fabric:

It is chiefly useful for the outfits that needs the body to be air dried quickly. This way it can protect the body and the material from bites of the insects. Also for the camping materials, equipment and gears this fabric is of use. Anything like totes and backpacks which require breathable material it can be used effectively.

Power mesh:

This technology is helpful in making outfits designed to smoothen the body, such as long-line panties, long-line bras, control slips and control top panty hose. These are more often used for making undergarments for women, although shape-wear and abdomen reducing undershirt for men are also made up of this fabric. The main advantage of the fabric is that it allows the skin to breathe and helps body to preserve its shape. It offers more comfort compared to the fabric like spandex and other stretchable fabric. Also it comes in various vibrant colors like red, cream, black, white and pink.

Tulle:

It is commonly used for manufacturing wedding veils. It is also used for wedding gowns, hats, evening gowns, lingerie’s and gifts as being a versatile fabric.

Nylon mesh:

This is porous in nature hence used for making birdcage covers, laundry bas, camper’s camp and tents. Its long lasting even its worn and torn out a nylon mesh patch can be used to repair it.

The facts remain the same that not only big brands are benefited but also young talented designers and small brands are taking advantage of it. Also the use of the 3D printers is not limited to commercial purpose; it has its own importance for personal use.

Thus, 3D printing techniques and technology has brought a remarkable change in a number of ways and helped people to unleash their creativity in various ways.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.