Although Prusa Research enjoys extraordinary popularity, the importance of the Czech company and its innovations is often underestimated. In our review of the Prusa MK4, we explore what sets the original apart from the imitations and reveal why Prusa is more important than many realize.

Prusa is undeniably one of the most respected names in the 3D printing industry and could even be considered the most important 3D printer manufacturer in the world right now – regardless of Prusa’s popular and internationally recognized portfolio of devices and materials, as well as its impressive sales figures. This bold assessment may only be fully understood by longtime industry members who have had the opportunity to observe multiple generations of users. They could see that Prusa’s products are used far beyond the boundaries of individual industries in companies of all sizes. It is particularly noteworthy that these devices can even be found in research and development departments of other additive manufacturing equipment manufacturers, where they support the development of products that potentially compete with Prusa. In addition, user feedback on the devices is consistently positive – a phenomenon that is extremely rare in this industry.

Influence far beyond its own borders

Another explanation lies in circumstances that many leading players in the additive manufacturing industry are often reluctant to discuss. One key point is that no additive manufacturing technology has nearly as high an installation rate as FDM technology, which is also used by Prusa. This discrepancy is so great that standard market reports cannot provide accurate figures. While major industry leaders measure their lifetime installation rates in a few hundred devices, only local customs authorities can estimate how many thousands of FDM devices are imported annually, many of which are clones of Prusa developments of different generations. This shows that Prusa’s innovations, in the form of more or less good replicas, shine far beyond what the Czech manufacturer’s sales figures suggest.

While a direct comparison between entry-level devices and industrial additive manufacturing equipment is not appropriate, Prusa exerts another significant influence that reaches deep into industrial sectors. When you talk to developers and users of industrial additive manufacturing equipment, you often hear that they learned the basics of additive manufacturing technologies on equipment from manufacturers in the RepRap movement like Prusa, and formerly Ultimaker and MakerBot. These companies and their open ecosystem have trained entire generations of enthusiasts to become experts in additive manufacturing, many of whom are leading the industry today. Many have acquired their skills not through formal education, but self-taught due to the lack of specialized training opportunities.

Despite the widespread recognition, there are also critical opinions of Prusa, mainly from interested parties who consider Prusa’s price to be too high compared to competitors from the Far East. In our current test, we take a closer look at this point. To do this, we ordered an original Prusa MK4 – the latest flagship device from Prusa 3D – to get a more comprehensive picture of Prusa.

Delivery and first impression

We received our fully assembled Original Prusa MK4, which was well packaged, and immediately set about our review. At Prusa, “fully assembled” means that you can actually take the device out of the packaging and place it on the table. Only the filament holder needs to be attached to the top and an optional tensioner fastened with three screws. The 3D printer is then ready for use.

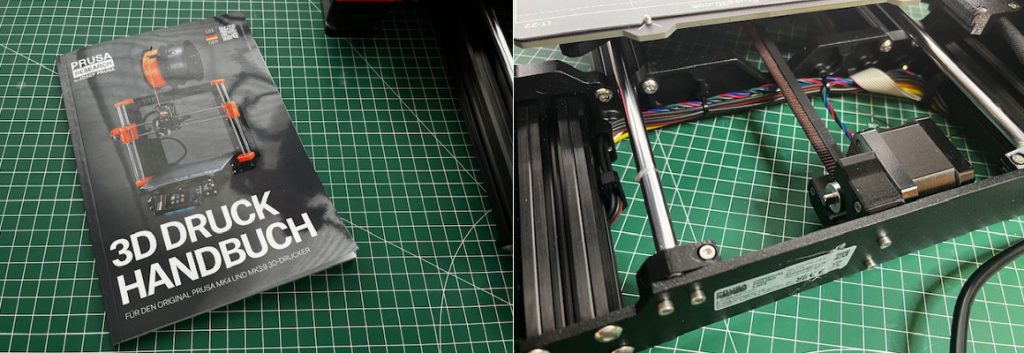

In addition to the printer (apart from the gummy bears, which we see as a friendly gesture), the package also contains the following standard accessories and components:

- Double-sided smooth PEI printing sheet

- 1kg of PLA powder

- 3D printing manual

- USB stick with sample prints (G-codes)

- Tool set: Uni wrench, wrench 13-16, Phillips screwdriver, needle-nose pliers, hexagon socket wrench and hexagonal T-wrench

- Alcohol-soaked wipes, acupuncture needle

- Spool holder

- Prusa lubricant for bearings

- A pack of Haribo gummy bears

- Manufacturing protocol

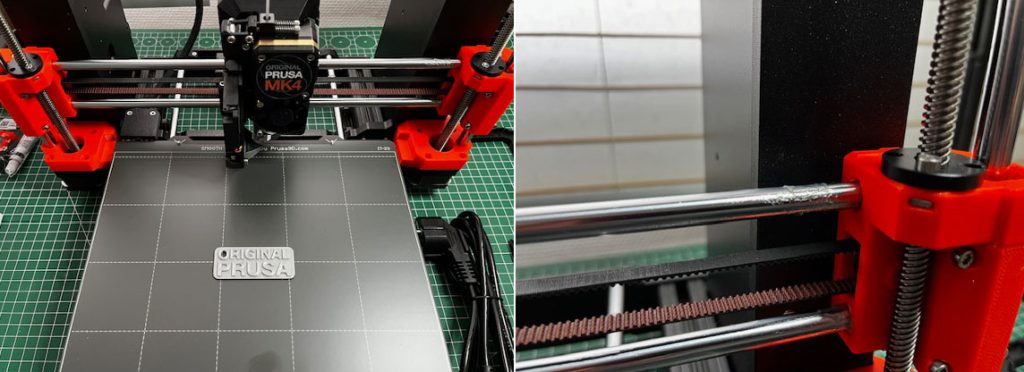

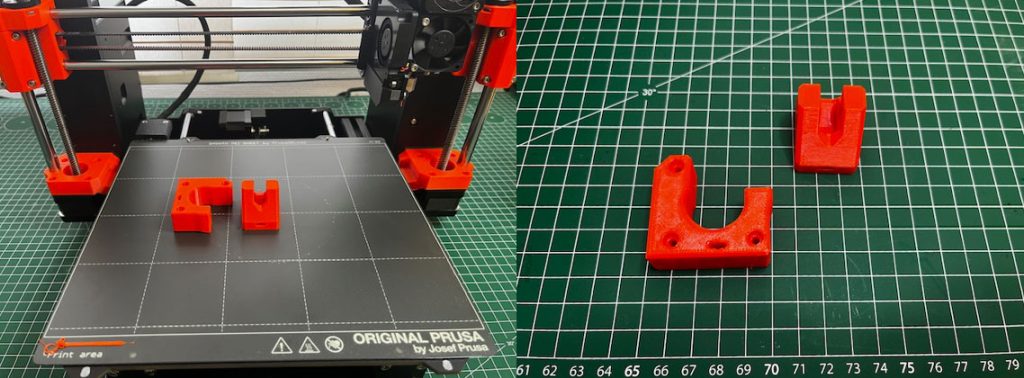

Our first impression is extremely promising and stands out from many other printers we have had the pleasure of testing in a few small but crucial details. Firstly, great importance was attached to the use of high-quality metals in this device, which immediately makes its stability stand out positively. There is nothing that wobbles, no loose screws, all cables are neatly secured with cable ties and the connection points are neatly reinforced. The authenticity of the in-house printed plastic parts on the printer underlines the confidence in the quality of the in-house technology. These parts, including the display housing, can also be reprinted as spare parts at any time.

In addition, all moving parts are visibly greased, which testifies to the high level of quality control at Prusa. Each device is individually tested and delivered with a test print (a key fob) directly on the print bed. Another plus point is the manual supplied, which really deserves its name. Not only is it available in your own language, but it also offers a real introduction to the world of 3D printing for beginners.

Functions and first test

As the successor to the famous MK3, the MK4 not only has to follow in the footsteps of an industry king, but also compete with an avalanche of rival products that are in a major price war. Many competitors are therefore pursuing a strategy of adding as many seemingly necessary features and gadgets as possible to their feature lists in order to stand out from the crowd. Prusa is not playing this game (for the time being), but is apparently focusing on proven and essential functions.

Technical specifications

The technical specifications of the MK4 are as follows:

- Build volume: 250 x 210 x 220 mm | 9.84 x 8.3 x 8.6 in

- Filament diameter: 1.75 mm

- Layer height: 05-0.30 mm

- Mainboard: Proprietary 32-bit xBuddy electronics with STM32

- Stepper motor driver: Trinamic 2130

- Stepper motors: Precise 0.9° X,Y stepper motors (prevents VFA)

- Extruder: Nextruder, Direct Drive, E3D V6 compatible (with an adapter)

- Extruder electronics: In-house developed breakout board for connecting fans, thermistors and other components.

- Filament path: Aluminum heat sink, all-metal hot end

- Drive system: Nextruder planetary gear system, 10:1 gear ratio

- Nozzle diameter: 0.4mm (standard) / other nozzle diameters are supported

- Maximum nozzle temperature: 290 °C / 554 °F

- Maximum heating bed temperature: 120 °C / 248 °F

- LCD screen: 3.5″ graphic 65k color screen

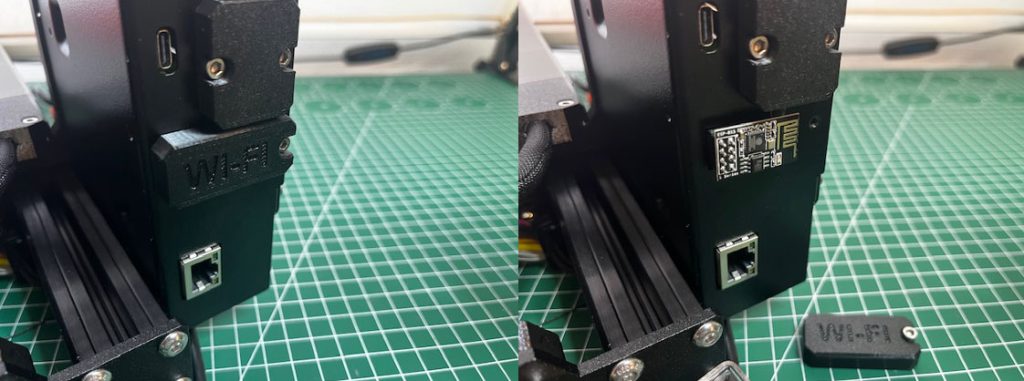

- Connectivity: Optional ESP Wi-Fi module

- Print medium: USB stick / LAN / Internet via Prusa Connect

- Advanced sensors: Filament sensor, load cell sensor, power panic, 4 high-precision thermistors (original Semitec) + fan motor speed monitoring

- Printing surface: Magnetic heating bed with removable PEI spring steel sheets

- Bed calibration: Automatic, grid bed leveling (only in the area to be printed)

- Supported materials: PLA, PETG, ABS, ASA, Flex, HIPS, PA, PVA, PC, PP, CPE, PVB, NGEN, composites and more

- Dimensions of the printer (without coil): 7 kg, 500×550×400 mm; 19.6×21.6×15.7 in (X×Y×Z)

- Power supply: 240W, customized by Delta with Power Panic HW

- Power consumption: PLA consumption: 80W / ABS consumption: 120W

While the device and installation space size, temperature ranges and layer heights of the MK4 are in line with the industry average for the entry-level series, this model lacks gadgets such as an integrated webcam, an SD card slot or a touchscreen. However, before you turn away disappointed, you should first take a closer look at the technical specifications directly associated with 3D printing, the value of which is not immediately apparent. The MK4 offers all the relevant functions that are actually required for trouble-free printing, including filament sensors, interruption protection, fully automatic bed calibration and a magnetic PEI printing plate. In addition, Prusa’s in-house development ensures an extremely harmonious balance between hardware, software and materials, which in our initial tests resulted in trouble-free and excellent print quality at high speed.

Equally relevant strengths of Prusa devices are even less immediately recognizable for newcomers. These can be found in the lively and active ecosystem that goes hand in hand with the device, as well as in the open standard that makes the device an absolute maker hit. These include not only the helpful support, a gigantic maker community, the high-quality 3D model platform Printables (which can also be recommended for users of other devices), reliable and intuitive software and a modular structure with excellent documentation that supports the use of spare parts, extensions and your own developments.

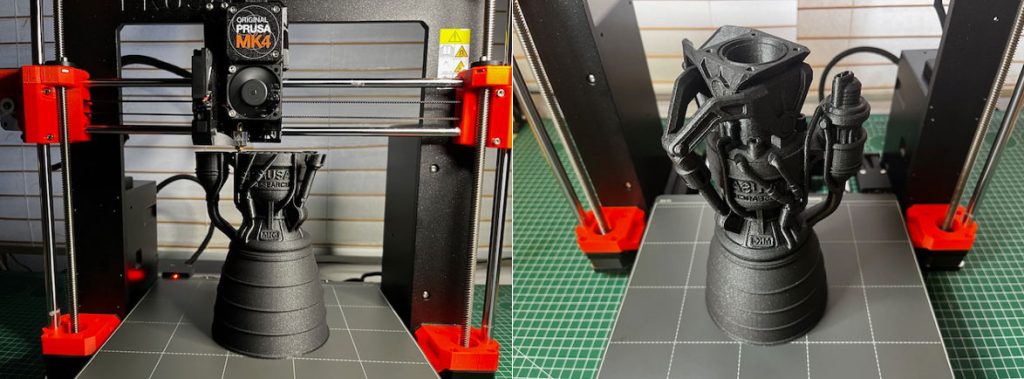

Printing tests

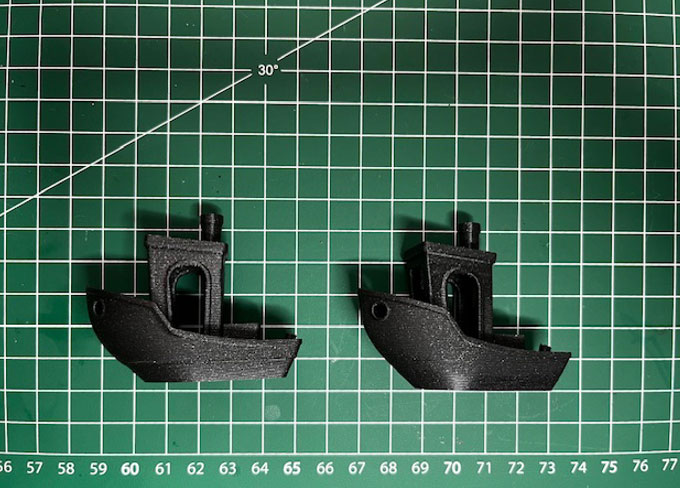

Our first test was accordingly boring or, from the user’s point of view, very good. In our print tests over several days (with original Prusa filament), we have so far been unable to identify any weaknesses in the print functionality of the Prusa MK4 when printing PLA and PETG (compared to many other devices in this class). All tests ran without any problems, which is rare, in excellent print quality, with hardly any to minimal stringing and fast. In terms of speed, the printer certainly keeps pace with the latest Klipper-based competitors and is comparatively quiet despite its open housing. Preheating, filament changing, automatic calibration and printing are all super intuitive and run at the highest level.

We also tested the power interruption during the printing process, which brings the extruder to a safe distance from the print object even after the power cable has been disconnected. When the power is reconnected, the printer continues the process fully automatically, although the point of interruption is still visible on the object.

We found a weak point in the integrated WLAN function, which also does its job, but surprises with an unusually cumbersome setup. You need a USB stick and a computer to save the access data and then establish a connection using PrusaConnect/PrusaLink. Historically, however, Prusa has proven time and again that users can rely on ongoing improvements via firmware updates.

Despite these minor issues, the printer convinced us in standard operation and we can end with a preliminary positive conclusion. The coming months will show how the printer performs in the long term.

Our preliminary conclusion

The Original Prusa MK4 can aptly be described as the Mercedes G-Class of entry-level 3D printers. Its design can be seen as either functionally simple or a timeless classic, but there is a broad consensus when it comes to reliability and quality. Although some gadgets that are sometimes standard with other manufacturers are missing from the data sheet, all of Prusa’s core functions work flawlessly – exactly the functions for which you actually buy a 3D printer, and without compromise. Prusa remains true to its path and does not allow itself to be influenced by short-lived trends. Instead, the company focuses on harmonizing software, hardware and materials to develop a reliable work tool that achieves outstanding results without a lot of bells and whistles and also fits perfectly into the Prusa ecosystem.

One point of criticism could be the price, which – similar to the Mercedes G-Class – could put off some potential fans. With starting prices of currently around €459 (original Prusa MINI+ kit) or €1199 (€889 as a kit) for our test device, there is a price discrepancy, but this is actually lower than some might expect. There may be a small price premium due to its cult status, but in our view the price is justified solely by the unique, active ecosystem and the lively, open community that supports a Prusa. The modular expandability and upgradeability not only offer excellent repair options, but also make the device compatible for future innovations, experiments and in-house developments. The fact that Prusa produces in Europe also makes a significant contribution to the local market and innovation system.

We conclude with a thoroughly positive conclusion. In our short test, the Prusa MK4 proves to be a worthy successor to the MK3. With noticeable improvements, without losing its soul as a cult device.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.