Fortify, a provider of 3D printers for advanced photopolymer composites, and polySpectra, a supplier of highly durable photopolymer resins, announced strategic funding from the U.S. Department of Energy (DOE) aimed at decarbonizing the U.S. industrial sector, advancing clean energy manufacturing, and improving America’s economic competitiveness and workforce diversity.

The DOE announced a selection of 30 projects that will receive $57.9 million in funding from the Advanced Manufacturing Office (AMO). The DOE awarded $3 million to polySpectra and Fortify, along with National Renewable Energy Laboratory, MPI Systems, RePliForm Inc, and Oak Ridge National Laboratory to develop durable direct additive tooling for automotive lightweighting via Cyclic Olefin Resin-based composites.

“More than $8B is spent domestically each year on low-volume injection molding. The work addressed by this DOE award will pave the way for printed injection molding to unlock production applications,” Josh Martin, CEO & Co-founder at Fortify said. “By combining advanced materials and post-processing with lightweight design principles, there is a significant opportunity to make a dent in the time to market, cost, and performance of part production within the automotive industry and beyond.”

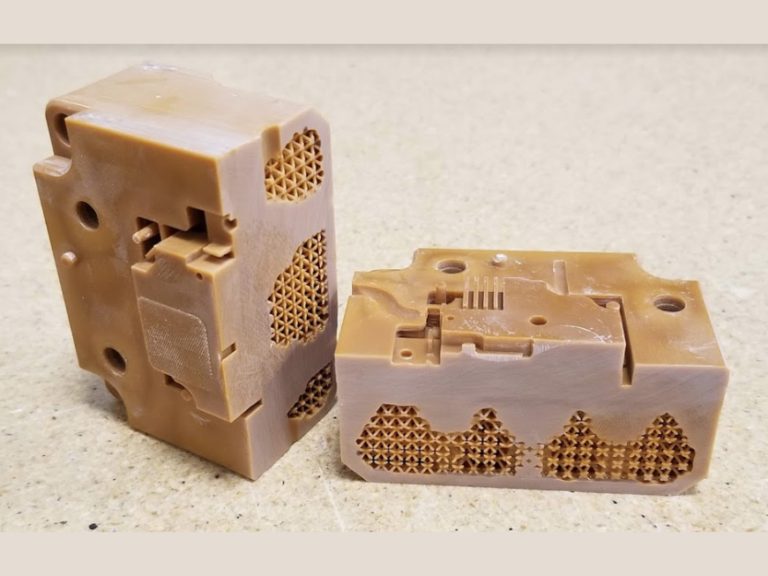

The goal of the project is to develop additively manufactured tooling with orders of magnitude improvements on cost and durability versus traditional CNC tooling, with cycle times on par with CNC tooling. Fortify has already positioned itself as a specialist developing robust solutions for additive tooling and, through this collaboration, will be developing a next-generation solution capable of producing long-lasting inserts for the molding of production volumes of lightweight automotive components from engineering-grade materials, including polymers, composites, and metals.

With a focus on automotive, the proposed work will address the critical need to develop improved methods for commercial vehicle part production. This advanced manufacturing technology will accelerate improvements in transportation vehicle fuel efficiency and realize the corresponding energy savings and emissions reduction.

The project also features significant efforts to amplify underrepresented groups in the automotive manufacturing sector by building skills in additive manufacturing and rapid tooling. Through training and recruitment programs, the team hopes to create a diverse pool of candidates with the necessary additive tooling skills to enter the automotive work force. Along the way, the project team will be mentoring and providing in-kind support to underrepresented innovators, including students and entrepreneurs.

Raymond Weitekamp, polySpectra founder and principal investigator for the award, shares that, “Olefin-based thermoset composites have been used for many decades in extremely demanding applications such as wind turbine blades and fuel cell components, because they are among the most durable materials on the planet. Under this research grant, we will leverage Nobel-winning chemistry to directly 3D-print these robust composite Cyclic Olefin Resins. The goal of the DOE project is to bring unprecedented materials durability to additive manufacturing, which will provide the industry with immense leverage for the decarbonization and reshoring of the US manufacturing sector.”

The joint project will begin later this year. You can see the latest developments in 3D printed tooling at Fortify’s booth #433114 this September at IMTS.

For more information about Fortify, please visit 3dfortify.com.

To learn more about polySpectra, visit polyspectra.com.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.