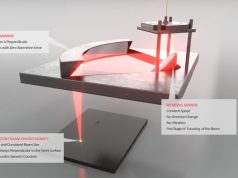

MetalFab 300 Flex from Additive Industries is a metal 3D printer with a flexible printing area. The company has now announced that K3D has ordered two models.

K3D, a leading service provider for metal additive manufacturing, was founded in 2014 as a subsidiary of Royal Kaak (formerly Kaak Group). Royal Kaak is a major manufacturer of industrial production lines for bakeries. Since 2016, K3D has been one of the early adopters of MetalFab technology from Additive Industries. This is mainly used to produce specialty products for the food industry that benefit from the design freedom of additive manufacturing.

Mark Massey, CEO of Additive Industries, commented: “We are delighted to partner with K3D as our launch customer for the MetalFab 300 Flex. Their decision to invest in our latest system highlights their confidence in our technology and their forward-thinking approach to business growth. The flexibility and scalability of the MetalFab 300 Flex will support K3D in meeting their expanding production demands while managing financial risk effectively.”

The expansion of K3D’s production capabilities is aimed at serving a broader range of industries such as aerospace, automotive, tooling, energy (including oil and gas) and defense. The investment in the MetalFab 300 Flex system is a strategic move to meet this growing demand. The focus is particularly on applications with stainless steel (316L) and titanium (Ti-6Al-4V).

The MetalFab 300 Flex offers K3D the flexibility to handle different application sizes without the high initial cost and ongoing depreciation of a large system. In addition, the system’s scalable architecture allows for incremental expansion, for example by increasing the build space or adding additional lasers, which supports risk-adjusted business development.

Luuk Wissink, CEO of K3D, added: “We are very pleased to be the launching customer for the MetalFab 300 Flex. This new business model approach from Additive Industries enables us to invest our capital in smaller increments, reducing our financial, commercial, and operational risks. The ability to expand our capacity and manage our footprint as our business grows is crucial, and the MetalFab 300 Flex provides the perfect solution.”

This strategic partnership between K3D and Additive Industries underlines the growing need for flexible and scalable solutions in the field of metal 3D printing and marks an important step in the further development of additive manufacturing technologies.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.