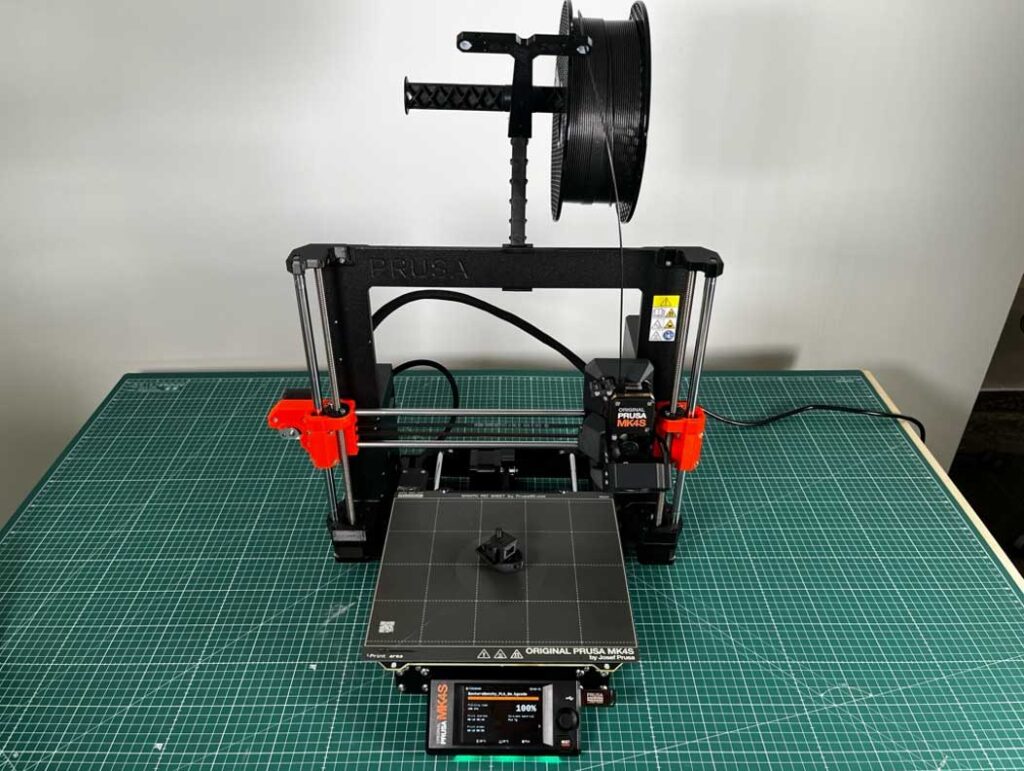

Just under a year after the introduction of the MK4, Prusa Research is already launching its successor, the Original Prusa MK4S. Once again, the company demonstrates its innovative strength and its attentiveness to the needs of the community. At first glance, the latest version closely resembles the proven design of its predecessor, but beneath the surface, numerous promising new features await. We had the opportunity to test the device in advance – and can report nothing but positive impressions.

Recently, we tested the MK4 to get a comprehensive view of Prusa’s quality and ecosystem. With the MK4S, Prusa takes it a step further: not only have all the shortcomings of the predecessor that we criticized been addressed, but significant upgrades have also been made in areas such as speed, overhangs, system openness, and connectivity. This effectively counters much of the previous criticism.

In the past, the addition of “S” or “S+” usually signified a collection of reliability upgrades, improved parts, and simplified maintenance. However, after just one year, the MK4S marks a significant leap forward. Here’s a brief overview of the new features:

- New high-performance 360° cooling with a completely new design

- New high-flow nozzle, custom-made in collaboration with Bondtech

- Native mobile app and one-touch Wi-Fi setup

- Parts of the device are now partially 3D-printed using PC Blend Carbon Fiber

- The LCD cover is now injection-molded

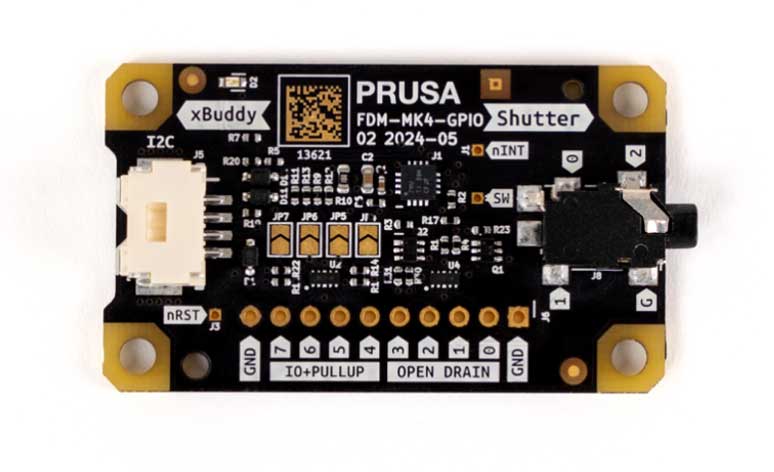

- Makers and modders will be pleased with an optional GPIO board

- New accelerometer support

In our review, we take a detailed look at these new features and evaluate their impact on the printer’s overall performance.

New Features and Review

The device arrived well-packaged in the fully assembled version, including the obligatory pack of gummy bears. As with the previous model, it is sufficient to take the printer out of the box, place it on the table, plug in the power cord, and attach the filament holder to the device. After turning it on, the printer is ready to use in less than 3 minutes if you skip the optional self-test. Even with the self-test, the device in our test was fully operational in about 10 minutes.

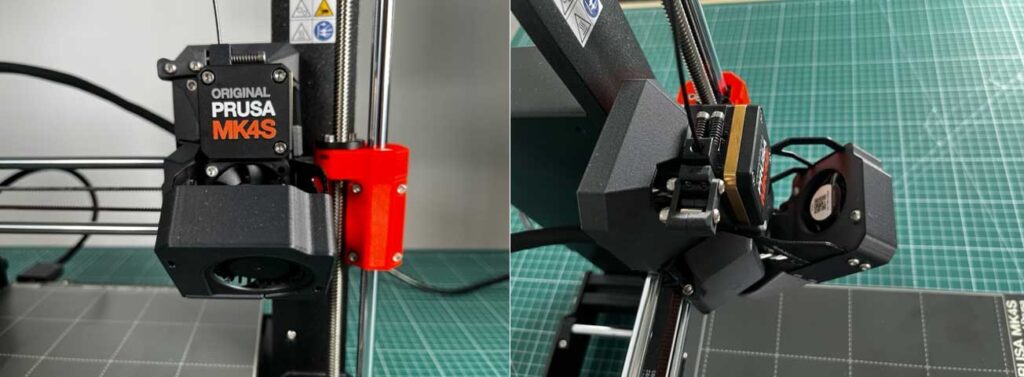

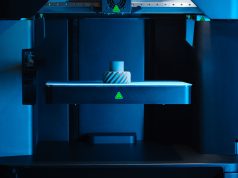

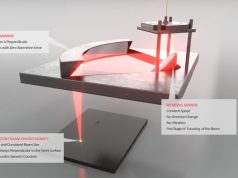

The most significant changes compared to last year’s model are the completely redesigned cooling system and a new high-flow nozzle. These innovations allow for significantly faster printing while maintaining top-quality and dimensional accuracy, as well as the ability to print steep overhangs of up to 75° without support structures. Visually, the new cooling system is the most striking feature that distinguishes the MK4S from its predecessor at first glance.

In a direct comparison with the MK4 (left), the MK4S (right) shows clear advantages when printing overhangs around 75° without support structures. This is especially noticeable on the undersides of the overhangs, as shown in the images below.

New 360° Cooling

Prusa has equipped the MK4S with a new high-pressure print cooling fan, which is mounted at an angle on the extruder to prevent hot air from being recirculated to the heatsink. This significantly increases the fan’s efficiency. According to the manufacturer, this configuration allows the fan to be turned off during up to 30% of the printing time without affecting the operating noise level. In our direct comparison with the MK4, we indeed could not detect any difference in noise levels.

The most important innovation of the redesigned cooling hood, however, lies in its ability to effortlessly cool overhangs of up to 75 degrees, saving both material and print time.

New High-Flow Nozzle

The MK4S also features a new, custom-designed high-flow nozzle developed in collaboration with the renowned company Bondtech. This nozzle offers improved performance through a higher maximum flow rate, making prints with STRUCTURAL profiles stronger and prints with SPEED profiles both more stable and faster. Additionally, the high-flow nozzle enables the creation of new, speed-oriented profiles with layer heights of 0.25 and 0.28 mm, further enhancing print efficiency.

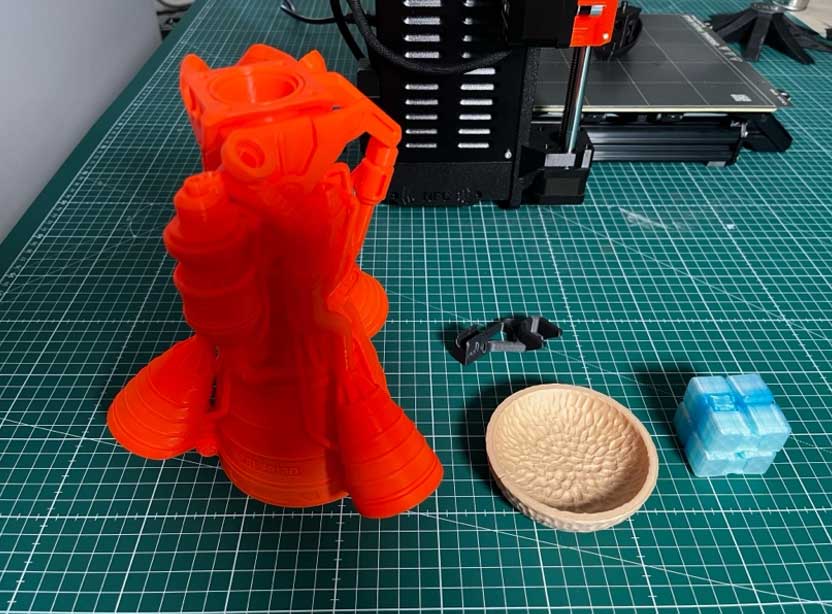

Depending on the filament used, the new nozzle allows for higher print speeds without compromising mechanical properties – a point often criticized in devices with Klipper firmware. However, this promise will only be fully proven in long-term tests. The MK4S printed our Benchy model in excellent quality in just 10 minutes. To provide better orientation, Prusa supplies a promising table with measured comparison values that underline the performance of the MK4S.

Native Prusa App with Improved Wi-Fi Setup

Surprisingly, Prusa is also introducing a native iOS/Android app that allows access to all printers remotely. This app will gradually integrate the features of the remote print management system Prusa Connect, including instant network printing, G-code streaming, scheduled print start, user teams, and much more. However, unlike some competitors, using the app or even connecting the printer online is entirely optional. Everything from 3D printing to firmware upgrades can still be done completely offline.

With this update, Prusa has also addressed our biggest criticism of the previous model: Wi-Fi setup is now easier than ever before. The MK4S can scan for available networks, and the password can either be entered directly via the touchscreen or transferred from a smartphone via NFC using the app. Alternatively, as before, a login file can be generated and used in PrusaSlicer.

At the product launch, the app already promises a comprehensive overview of all 3D printers and print jobs, allows starting, pausing, and stopping prints directly via Printables.com, and sends push notifications for ongoing print jobs (e.g., print finished, filament change). The app is also set to be continuously expanded with new features to offer even more control and convenience.

New Materials and Production Processes Used

Not immediately apparent are the new materials and production processes used in the MK4S. Many parts that were originally 3D printed in PETG have been replaced by the durable and temperature-resistant Prusament PC Blend Carbon Fiber. However, some components that require higher ductility are still printed from PETG.

A noteworthy innovation at Prusa is the in-house injection molding production of the LCD cover. Prusa explains this step as a way to increase capacity in their 3D printing farm and improve overall efficiency. Additionally, the MK4S uses a special low-friction injection molding material for the Nextruder’s gear cover, which allowed two components (the cover and a special low-friction spacer) to be combined into one unit.

Despite these internal production changes, Prusa continues to provide 3D-printable alternatives to the injection-molded parts on Printables.com, allowing users to produce their own replacement parts.

GPIO Board

With an optional GPIO board, the MK4S provides modders, hackers, and tinkerers with a new accessory. The GPIO board connects to the MK4S mainboard and can easily be programmed with custom G-code commands or pre-made code from others. Prusa expects this to generate a variety of community-driven innovations.

Accelerometer

With an optional GPIO board, the MK4S offers modders, hackers, and tinkerers a versatile new accessory. This board connects directly to the MK4S mainboard and can easily be programmed with custom G-code commands or existing code. Prusa hopes this will lead to a variety of community-generated innovations that will further expand the printer’s capabilities.

Our First Conclusion

In our brief test, the MK4S, like its predecessor, impresses with reliable, repeatable, and high print quality at impressive speeds, even with different materials. The significantly improved user-friendliness and the visible strengths in support-free overhangs complete the positive picture.

Prusa Research has further improved an already excellent device, successfully addressing all the points of criticism we raised in the last review. This proves once again that Prusa not only listens to the community but is also capable of keeping the competition at bay with its own clever developments – and all without compromising quality in favor of ever-increasing numbers and new features.

The MK4S replaces the current MK4 model and will be offered as both a kit and a fully assembled version at the same price as the MK4. As is typical with Prusa Research, an upgrade package is also available for the MK4S. Instead of replacing the existing printer, owners can simply upgrade to the newer model. The upgrade kit, priced at $99, allows all MK4 owners access to the new features of the MK4S.

The MK4S 3D printer costs $799 as a kit in the official store. The assembled 3D printer costs 99. With the discount code “3Druck“, customers receive a free Prusament Filament-PLA spool with orders placed before August 26, 2024.

@3printr Prusa Research presents its latest 3D printer Original Prusa MK4S. With the special discount code "3Druck" you get a free filament spool of Prusament PLA with every 3D printer. #3dprinter #3dprinting #prusa #prusaresearch #additivemanufacturing ♬ Beat Automotivo Tan Tan Tan Viral – WZ Beat

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.