Every year, millions of people around the world die from lung diseases. Treatment options are limited, and animal models to study these diseases and experimental drugs are inadequate. Now, researchers in ACS Applied Bio Materials describe their success in creating a mucus-based bio-ink for 3D printing lung tissue.

Lung diseases claim millions of lives worldwide every year. Although some patients receive lung transplants, the availability of donor organs remains limited. Alternative treatments such as drugs can only alleviate symptoms but do not provide a cure for diseases such as chronic obstructive pulmonary disease (COPD) and cystic fibrosis. The search for better drugs often involves testing on rodents, but these models often only partially capture the complexity of human lung disease and cannot always accurately predict the safety and efficacy of new drugs.

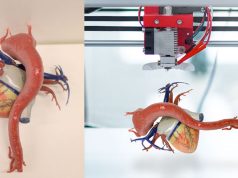

Bioengineers are therefore exploring the production of lung tissue in the laboratory as a more precise model for studying human lungs or as a potential material for implants. One method is to print structures that mimic human tissue, but developing a suitable bioink to support cell growth is a challenge. To overcome this obstacle, Ashok Raichur’s team turned to mucin, a previously under-researched component of mucus.

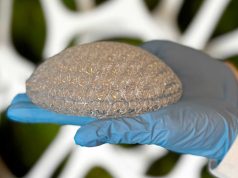

Mucin, a component of mucus, shows segments in its molecular structure that resemble epidermal growth factor and promote cell growth. The team modified mucin by reacting it with methacrylic anhydride to produce methacrylated mucin (MuMA). This was then mixed with lung cells. Hyaluronic acid was added to increase the viscosity of the bioink and improve cell growth and adhesion to MuMA. The printed structures were then exposed to blue light to cross-link the MuMA molecules and create a stable, porous gel structure that absorbs water and supports cell survival.

The researchers found that the interconnected pores in the gel facilitate the diffusion of nutrients and oxygen, which promotes cell growth and lung tissue formation. The printed structures were non-toxic and degraded slowly under physiological conditions, making them potentially suitable for implants where the printed scaffold is gradually replaced by newly grown lung tissue. The bioink could also be used to produce 3D models of the lung to better understand disease processes and evaluate potential treatments.

These advances in 3D printing could therefore significantly advance both research into lung diseases and the development of new treatments.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.