Metal additive manufacturing technology has received significant support from governments and medical organizations in recent years and is becoming a key technology in the manufacture of medical products. The combination of this technology with healthcare now permeates every stage of medical processes – from pre-operative planning to surgical implants and post-operative rehabilitation. In particular, products manufactured using laser powder bed fusion (LPBF) technology are increasingly penetrating the market, offering the healthcare industry innovative and flexible solutions that improve both performance and adaptability.

The development of standardized medical devices and implants has undergone a significant transformation through the application of LPBF. This technology makes it possible to mass produce complex, porous implants, which is particularly evident in the production of spinal fusion elements and acetabular cups. Metal 3D printing not only speeds up the development process, but also reduces material waste and production costs. In addition, the selection of biocompatible metals allows optimal material utilization, which supports the long-term durability and integration of the implants in the body.

In addition to standardized implants, metal additive manufacturing also opens up new possibilities for tailor-made medical products. As the demand for precise medical solutions grows, doctors can now develop implants that are specifically tailored to patients’ individual defects. These customized implants are precisely adapted to the patient’s anatomy using imaging technologies, ensuring high precision and functionality. Rapid prototyping and the ability to manufacture a customized implant within 24 hours allows for optimal timing of treatment while increasing surgical safety and reliability.

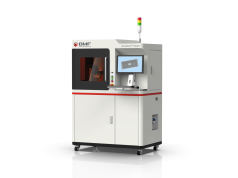

BLT, a leading provider of metal additive manufacturing solutions, has developed comprehensive turnkey solutions specifically for the medical industry, covering the entire process from the design phase to the finished product. These solutions include advanced printing machines, software, materials and processes tailored to the specific requirements of the medical industry. BLT works closely with partners and renowned hospitals to fully exploit the potential of metal 3D printing technology and take it from research to clinical application.

Overall, the development of metal additive manufacturing marks an important step towards personalized, efficient and precise medical care. The technology makes it possible to create customized solutions that are specifically tailored to the needs of patients and offers the medical industry new ways to treat complex orthopaedic conditions.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.