Manufacturers are currently required to integrate the increasing number of drive concepts and energy storage systems into vehicle structures. Particularly in light of alternative drive systems in small batches with lots of different versions, the vehicle bodies of tomorrow will not only need to be lighter, but above all will also require a highly flexible design. The consequence is an increasing number of vehicle derivatives which demand adaptable bodywork concepts that are economical to manufacture. In the foreseeable future, additive manufacturing will be able to offer entirely new conceivable approaches.

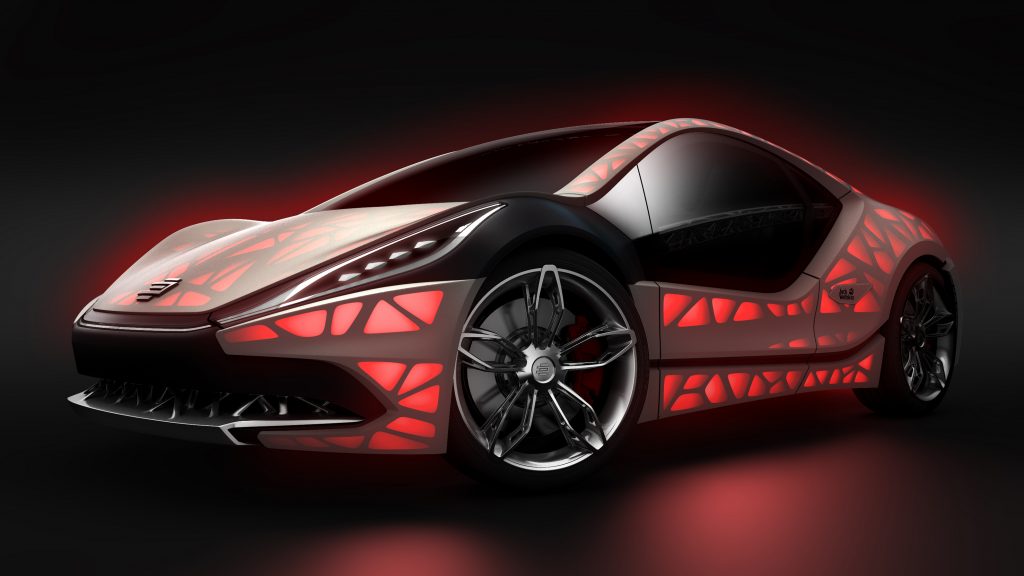

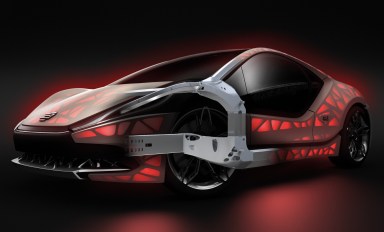

In a joint project, EDAG Engineering GmbH (Wiesbaden, Germany), Laser Zentrum Nord GmbH (Hamburg, Germany), Concept Laser GmbH (Lichtenfels, Germany) and the BLM Group (Cantù, Italy) presented the bionically optimized spaceframe produced by hybrid manufacturing to highlight a new way in which a bodywork concept that is adaptable and can be manufactured flexibly can be produced in order to make the increasing range of different vehicles manageable thanks to the large number of different drives and load stages. Additively manufactured bodywork nodes and intelligently processed profiles are combined. Thanks to additive manufacturing, the nodes can be configured to be highly flexible and multifunctional so that, for example, different versions of a vehicle can be produced “on demand” without any additional tooling, equipment and start-up costs. Steel profiles are used as connecting elements. They too can easily be adapted on an individual basis to the specified load levels by providing them with different wall thicknesses and geometries. The NextGen spaceframe is part of the EDAG “Light Cocoon” concept car, a compact sports car with a bionically configured and additively manufactured vehicle structure, covered with an outer skin made from a weatherproof textile material.

We spoke to all of the partners involved in the project about the new approach of a lightweight frame optimized for manufacturing.

Editorial team: Is it becoming more difficult in the automotive sector to achieve the sustainability targets? If it is, what contribution is the hybrid NextGen spaceframe design from EDAG making?

Martin Hillebrecht: Automotive manufacturers are under great pressure to develop vehicles which are due to go into production between 2015 and 2020. The new bodywork structures should weigh less, have high stiffness to ensure outstanding performance and satisfy demanding load scenarios in the event of a crash. In spite of all the ambitious targets for weight reduction, greater demands from customers, thinking of alternative drives, comfort, functionality and networking, as well as new safety requirements from international legislators are sales criteria that do not favor lightweight construction. From my perspective, the core concept of a visionary and bionic spaceframe would be among other things only to use materials where they are really needed to deliver a function, safety or rigidity. So a reduced approach based on the motto “less is more”. Thanks to toolless additive manufacturing and the profiling method with minimal use of tools, it may even be possible in future to design all bodywork versions to suit the level of loading and manufacture them “on demand”. Whatever happens, there is definitely potential here.

Sergio Raso: Sustainability is the overriding aim for the automotive industry. Various core technologies for the future of automotive production have so far been looked at. The frame structure of the EDAG Light Cocoon combines many of these technologies in one approach. For example, there is a lightweight hybrid design to achieve weight reduction and fuel efficiency, use of additive methods for a bionically optimized design and use of tubing and profiles to ensure that the vehicle frame can be manufactured in a highly flexible way.

Editorial team: As the example of electric vehicles in Europe demonstrates, it takes a long period of time to progress from initial innovators such as the pioneers Hayek (original Smart) or Tesla Motors (USA) to get to adapted innovations. Is the automotive industry really ready to look at its products in completely new ways?

Martin Hillebrecht: Experience shows that one possible way to embark on new manufacturing strategies such as lightweight design is often to produce small numbers of vehicles in the luxury car and supercar segment. This clientele identifies with lightweight design, e-mobility and technical innovations much more than the mass market. These “innovators” are willing to accept much higher manufacturing costs as a price worth paying for better driving dynamics, comfort, safety and for ecological reasons. If the technology displays suitable potential and as its development advances to allow mass automotive production, the processes can then be scaled up from a niche product to enable larger volumes to be produced. But this definitely requires a degree of patience, long-term investments in the future of the companies involved and a great deal of technical expertise. I don’t accept that “a long period of time” is required, but it definitely takes some time to adapt new technologies.

Sergio Raso: In the automotive industry, the number of jobs depends to a large degree on the manufacturing methods and strategy employed. They have a crucial bearing on the cost structures, the achievable margins and the level of success. These factors shape the way we look at mobility and not least also the prosperity of many national economies. In order to maintain the level of automotive mobility that has been achieved, the automotive industry has continuously invested in making technological advancements to its automobiles and the production processes behind them. Investments in research and development are essential, and we at the BLM Group are also on this path of innovation and ongoing development.

Editorial team: Conservation of resources and “green technology” are key aspects. How does the automotive manufacturer view this?

Martin Hillebrecht: Thanks to smart lightweight design, particularly with composite construction, the vehicles should be roughly 100 kg lighter than their predecessors, depending on the segment of the market. A further weight saving of from 10 to 20% can be achieved in the bodywork and add-on parts. Many manufacturers have already succeeded in reversing the spiraling trend for increased weight. But what is also true is that in spite of all the ambitious targets for weight reduction, the greater demand from customers for alternative drives, comfort, functionality and networking as well as new safety requirements from international legislators are sales criteria that do not favor lightweight construction. It is a balancing act that we are trying to achieve.

Sergio Raso: Solutions for “green technologies” and intelligent energy management are heavily dependent on action by governments, with their political targets, laws and definitely also the incentives that they provide. This focus, if we just look at the US state of California, is an increasingly prevalent fact that we must come to terms with. Automotive manufacturers are accepting these demands and also view political targets as an engine for driving innovation. So politicians and manufacturers share a common interest. Along with the known solutions for energy management, such as developing electric storage units and drives, and also vehicles equipped with fuel cells, the manufacturing processes can also be heavily geared to reflect the visions of “green technology”. The manufacturing design with all-electric bending machines, laser cutting machines with a high level of efficiency or laser melting are examples of how the BLM Group is committed to a “greener” future. The path toward intelligent conservation of resources and sustainability is an irreversible mega trend. All of the stakeholders in the automotive industry are conscious of this.

Editorial team: Please briefly outline the advantages and disadvantages of conventional body designs.

Claus Emmelmann: Today’s car bodies are intelligent, load-optimized and crash-optimized structures whose material and design concepts have achieved a high level of maturity. Both in terms of lightweight design and passenger protection. The traditional tool-based manufacturing methods which are used are reaching their limits in terms of flexibility and feasibility. Laser Zentrum Nord was able to work with its project partners to overcome these limits conceptually with the bionic design principles modeled on nature. The spaceframe concept attempts to highlight what is possible “beyond limits” with regard to products, manufacturing and automation.

Martin Hillebrecht: In a typical car body with a monocoque construction, panels, reinforcements, mounting plates and profiles are connected together using joining technology. All components act as shells. The required rigidity is produced by cross-sections of metal sheets. The advantage of this design is the low manufacturing costs associated with industrial mass production which is the same worldwide. As well as inexpensive semi-finished products made from sheet metal, tried-and-tested and robust technologies such as forming and spot welding are used. The disadvantage here is that tooling and plant investments only make economic sense if there are large quantities and make it difficult to produce a wide variety of different versions. In addition, tool-specific parts are associated with tooling costs and periods of preparation for the tooling technology are required. Ultimately, the tools have to be available across the full life cycle of the product. A spaceframe design consists of closed hollow profiles which are linked together by nodes. Flat components such as the roof absorb the shear forces. In future, a spaceframe concept will enable new materials to be used. This will need to be investigated. But in general it is already the case today that the concept enables the manufacturer to achieve a significant weight saving and high torsional stiffness along with a high level of economic efficiency for vehicles produced in fairly small numbers.

Sergio Raso: A major advantage of the conventional structures for vehicle frames is the interplay between consolidated technologies which are available nowadays for manufacturing and assembling the frame. Nowadays production lines must generally include various processes and phases prior to the final assembly of the vehicle frame. The disadvantage of this concept is the outlay and the limited flexibility in the assembly workflow. New ideas and, derived from them, economical and flexible concepts for future manufacturing are required here. I would put it this way: There are major challenges.

Editorial team: What features and new processes does the NextGen spaceframe concept have?

Martin Hillebrecht: The jointly devised steel spaceframe node combines additively manufactured nodes based on “selective laser melting” with intelligently processed profiles with a hybrid design. This approach promises to make production extremely flexible. And it promises the possibility of a wide range of different versions without having to spend any money on making further investments in apparatus, tools and plant technology for each version of a vehicle. I think that a wide range of different models may emerge because restrictive cost barriers will no longer apply. In addition, additive manufacturing allows the greatest possible resource efficiency with regard to the materials that are used. Moreover, this process yields bionic structures with optimized load paths whose geometry means they simply cannot be produced using other manufacturing methods.

Claus Emmelmann: The spaceframe concept combines the advantages of 3D printing, such as flexibility and the potential for lightweight construction, with the efficiency of a proven conventional profile design. The laser plays the key role in both technologies. The bionically optimized nodes enable the maximum lightweight construction that is possible at the present time, and a high degree of functional integration. Both the nodes and the profiles can be adapted to new geometries and load requirements without any additional outlay. This means that they offer the possibility of designing every single part to cater for the level of loading, and not dimensioning the components to reflect the greatest motorization, as was previously the case. The basic idea then is to have a frame design which can be optimally customized to reflect what the particular model requires.

Sergio Raso: The main feature of the NextGen spaceframe concept is a consistent focus on the manufacturing and assembly processes being extremely flexible. Additive manufacturing technologies along with profiles which are easily bent and can be produced by 3D laser cutting provide possible ways to enhance flexibility. Additively manufactured free-form nodes enable new design solutions and a large number of different varieties of models. The incorporation of bionic structures, a hollow design or lattice structures allows the frame to display optimized mechanical properties. The integration of force absorption characteristics in the profiles and nodes permits controlled deformation of the frame and delivers increased safety for passengers. The inclusion of AM and configuration of interfaces for laser welding optimizes the manufacturing process. So firstly flexibility, secondly safety and thirdly simplification of processes are just a few examples of the advantages of this approach.

Frank Herzog: I would just like to add here that hybrid construction is also already being used in other sectors. Relatively simple or excessively long geometries, such as the profiles here perhaps, are produced by traditional machining, and more complex geometries are then manufactured additively. This phenomenon reflects the economics. Composite construction is of interest in many sectors where there is a need to bridge a gap between function and economic efficiency.

Editorial team: What new manufacturing strategies and potential for automation will emerge from this in the future? What potential do you see in construction and manufacturing?

Claus Emmelmann: The potential for construction resides in flexible design that caters for specific load situations. And the opportunity to use the bionic structures that have been highlighted to engage in the maximum possible level of lightweight design on a scale that was not previously possible. At Laser Zentrum Nord we develop design guidelines to be able to successfully transform bionic prototypes such as a bamboo structure or bird-bone structure into such sophisticated technical lightweight components with weight savings of generally from 30 to 50%. Bionic design, which is possible thanks to additive manufacturing, provides numerous options. Manufacturing benefits from the new manufacturing methods in many ways: It is not just that the costly tools are no longer required, but flexible small batches or even modifications to components within the life cycle of a model can be produced instantly without any additional outlay.

Martin Hillebrecht: In addition, the ability to respond to fluctuations in sales volumes and “updateable” components during the life cycle of a vehicle in the sense of “adaptive Industry 4.0” should be emphasized. These are completely new ideas for the industry. We are very excited to see how our customers will react to this.

Sergio Raso: The new concept means great freedom of design for developers and designers. The proposed concept provides the designers in the automotive industry with more lightweight solutions, more ecological approaches and improved safety solutions. In manufacturing, the adaptation of laser-based methods, such as additive manufacturing of nodes, laser cutting and laser welding of tubes and profiles, means an unparalleled degree of flexibility. Not least, these manufacturing strategies may help to increase the level of automation. These methods represent the innovation of manufacturing processes.

Frank Herzog: I thank Dr. Hillebrecht for referring to “Industry 4.0”. The core aspects of this concept such as automation, digitization and interlinking play a fundamental role in our recently presented “AM Factory of Tomorrow”. The objective is to automate and thus minimize manual processes in order to prevent any downtime in the production of components. Any desired number of machines which were previously designed to be stand-alone solutions will increasingly be linked together to embrace the notion of a smart factory. There will also be automation and interlinking of additive and conventional technologies, in particular in the reworking of the components that are produced. Traditional manufacturing methods will then operate alongside additive methods. Our “AM Factory of Tomorrow” is aligned with the requirements of the basic idea behind Industry 4.0 and in the future will also make our process economically attractive for the mass production of metallic components. This will then undoubtedly also apply to the automotive industry where it is primarily all about large volumes and quantities.

Editorial team: What significance does the powder-based laser melting of metals have today and what significance will it have in the future in the automotive industry?

Claus Emmelmann: It is now impossible to imagine prototyping in the automotive industry without the 3D printing of metals. This process makes it possible to produce fully resilient trial parts quickly and without the high tooling costs that are otherwise customary. However, the move to mass production has not happened yet. But the continuous increase in the productivity of 3D printing machine technology means that this step will be made in the next five to ten years. The two projects which were presented at the IAA trade show (2015), the bionic spaceframe and the housing for power electronics, demonstrated two specific ways in which this technology may shortly be employed economically in electric mobility vehicles or even other vehicles produced on a small scale.

Sergio Raso: Additive manufacturing techniques are today employed primarily in the automotive industry to manufacture small numbers of functional parts. However, as the aerospace industry has already demonstrated, we can see that the move over to additive manufacturing strategies significantly enhances product and process performance. The introduction of the “Manufacturing for Functionality” paradigm instead of the rather restrictive “Design for Manufacturing” as well as “just-in-time manufacturing” and precision concepts have already begun to establish a foothold in the automotive industry. We are seeing the foundations of something completely new here.

Martin Hillebrecht: Nowadays the additive processes provide great potential in prototyping and tooling and the production of spare parts. These processes have so far not caught on in automobile production. This is undoubtedly also due to the high prices of materials and machine technologies. We await the future with keen interest. We would be delighted if the sector were to embrace our ideas of tool-free manufacturing in combination with traditional manufacturing methods. There are definitely lots of opportunities here.

Frank Herzog: The level of interest will increase the more the level of additive manufacturing technology advances. A high level of acceptance in the automotive industry can of course only be expected if, as in the aerospace sector, the new design possibilities that additive manufacturing brings are embraced. Simply substituting parts made using traditional methods delivers few advantages. It is all about having a design to suit the method – and these parts then look different, are lighter and are often probably also more capable.

Editorial team: Thank you for pointing out the design aspect. How will this change the design or project workflows for structural elements in the automotive sector? What else will change in the future?

Martin Hillebrecht: The development process chain including the requirements specification and topology analysis, development of functions, bionic design and production-oriented design is not yet established and still takes up a great deal of time. CAD and CAE will increasingly merge together. Overarching CAx competence will be demanded. In addition, we require bionic components and tools, not least a working interface with the laser melting machine, so that “anything imaginable really could then be printed”.

Sergio Raso: The use of 3D-bent and laser-cut tubes and profiles for structural assembly has already proved to be a way of saving weight in assembly while still retaining the mechanical properties. In this design, the load-specific matching of laser-melted 3D nodes and laser-welded 3D profiles has an important role to play. Nodes produced by traditional casting technologies proved to be a trusted solution in the past. Thanks to bionics, hollow spaces and lattice structures, additive manufacturing now allows the 3D nodes to have even more options for design, variations and safety aspects. I see this as an important next step.

Editorial team: Can a new concept like the EDAG Light Cocoon have an influence on the demand of car buyers?

Sergio Raso: Nowadays cars encapsulate every single person’s “expression of freedom” like almost nothing else. The Cocoon’s light concept undoubtedly makes people “feel good” out on the road. However, today’s consumers focus primarily on practical aspects such as costs, safety and the reliability of the brand. The concept of a lightweight hybrid design must therefore remain realistic and for now can only really offer a glimpse into the future. It is a possible step toward innovation. It will of course take a great deal more effort and possibly a long time to gradually steer established purchasing choices in a new direction.

Martin Hillebrecht: Unlike the vehicle’s interior and exterior design, materials do not directly influence the purchasing choice made by the end consumer, but they are essential to consider in examining the economical production and functionality of a vehicle. Intelligent composite designs are just as important in lightweight construction as the energy and resource efficiency of vehicles in a global context. One aspect in particular matters to me: Visible bionic structures in the vehicle with their positive image in society, produced using the futuristic technologies of additive manufacturing, might initially mean that end customers also make exciting decisions when it comes to materials. How many euros of additional costs per reduction in kilogram as a result of bionic solutions would the various customer segments be prepared to pay to switch – this can only be speculated on.

Frank Herzog: That’s right. Here we can only speculate. But it will still take some time for the benefits of additive manufacturing to also become established in the lines of argument used in advertising by the automotive industry. But the issue of sustainability has already taken hold.

Editorial team: Talking of lightweight design and bionics: The reduction in weight seems to be a clear advantage. Where are limits encountered for safety-relevant components and in crash tests?

Sergio Raso: The suggested concept can highlight clear advantages for safety-relevant components. If there is an accident, functionalization of the 3D profiles and 3D nodes ensure controlled deformation of the frame. Simulations have already shown that the interaction between nodes, cross members and longitudinal beams significantly improves performance under crash conditions. The dissipation of mechanical or kinematic energy is far better compared to a conventional frame structure.

Martin Hillebrecht: In the case of components which are stressed in a crash, e.g. the longitudinal beams and A-pillar nodes, energy is dissipated away by “defined buckling” of the beam. A corresponding CAE method for optimizing the crash performance of bionic components has recently become a new and exciting topic for research and development. In addition, the range of materials on offer for use in additive manufacturing has not previously been matched to the requirements of automotive manufacturers. We are frequently asked to provide support and practical help here. Additive strategies change everything: structures, functions, choice of materials – and the possible range of quality and services.

Claus Emmelmann: Bionically optimized and printed 3D parts are on a par with conventional components when it comes to component strength. The material and component properties can be adjusted to specific applications through targeted after-treatment of the component, for example sandblasting or thermal treatments. Essentially, it is now possible for the first time to “design” performance characteristics in a convincing way. At Laser Zentrum Nord, the employees working in the area of research and development are engaged among other things with the issues of component optimization, process qualification, quality assurance and also the calculation and targeted modification of key material parameters. Bionic optimization offers the opportunity to use the material in an optimum way that reflects the load situation and thus implement maximum lightweight design.

Editorial team: The automotive industry is volume-driven and thinks in terms of high quantities and platform strategies in order to manage costs. How can the new approach of a concept car such as this stand up to these traditional attitudes?

Sergio Raso: It is difficult to believe that the new hybrid lightweight design can lead to an immediate sweeping innovation in the mass production of frames for cars. A more realistic scenario is that the new concept will be adopted for small batches of high-value automobiles while alongside this traditional design paradigms are retained for “low-cost” mass production. A “best of both worlds” mindset could become established. That would be realistic in my view.

Martin Hillebrecht: Our project is currently not appropriate for the cost-minimized production of a global mass product from “low-cost” aspects. What we aspire to do is to use the concept to highlight “high tech for the premium segment”. The appeal is of course also to consistently utilize enhanced functions and automation to boost Europe as a place for engineering. I am also convinced that a consistent concept can only emerge if a large number of electric and non-electric alternative drives for vehicles also come into play as a general requirement. After all, the theme is only really just developing.

Frank Herzog: Experience shows that innovations in the automotive sector first emerge in the premium segment. We only need to think about things like the airbag, LED lights or ABS. An innovation then gradually works its way down the product range. There are “economies of scale” here which have a positive effect on costs. If we assume that the costs of a kilogram of laser-melted products will fall over the long term due to technical progress, then the issue of additive manufacturing becomes more and more interesting to those in the automotive industry. According to the experts from Roland Berger, in 2012 the average price including all of the AM processing costs, so for machine technology, powder, energy costs, reworking, etc., was around 3.14 EUR/cm³. These analysts predict a price of around 1.60 EUR/cm³ by 2018. 1.10 EUR/cm³ has been estimated for 2023. All I want to say here is that there is probably a clear trend illustrating that there will be plenty of movement on the cost side.

Editorial team: Spare parts for cars are regarded as a logistical and costly challenge. Global availability, warehousing, life cycles and the pressure of time are all challenges for the spare parts experts. Not least, spare parts are currently a blessing for automotive suppliers that operate as OEMs or retrofitters or even duplicators. How can additive manufacturing change this situation?

Martin Hillebrecht: Additive manufacturing makes it possible above all to fabricate components spread out and at different locations. This means that local advantages can be exploited, and different versions can be produced later and close to production. There are thus no transports and logistics costs, different versions of components no longer need to be kept in stock, and production close to the market and customers shortens the delivery time.

Claus Emmelmann: Additive manufacturing makes it possible to no longer send physical components around the world but instead simply send CAD data records and then, if necessary, print out spare parts at a local level. One option is to have decentralized manufacturing, the effects of which we can only imagine. This approach will radically alter the supply of spare parts – delivery times will be reduced significantly and warehousing costs will be completely removed. This scenario is currently being actively implemented with the aviation industry. The foundation is thus being laid for this approach to be transferred to the automotive industry too.

Sergio Raso: Car frames based on 3D-bent and cut profiles and nodes produced from additive manufacturing will also enable new paradigms for the management of spare parts and their logistics. Fully automatic production of profiles and nodes based on “just-in-time” approaches would enable a drastic reduction in costs, also assuming that new guidelines for the repair of vehicles will be adopted.

Editorial team: What general changes as a result of 3D strategies do you envisage for vehicles in the future?

Martin Hillebrecht: Additive manufacturing processes will move away from the traditional areas of application of rapid prototyping or industrial prototyping. They will operate alongside the traditional manufacturing processes and give a new dimension to the possibilities of constructive design. For me this is in fact radical. Additive manufacturing will make it possible to create very complex, functionally integrated and highly efficient structures that cannot be produced using other methods. It will therefore be possible in future to design complex components with a customized design for products available in lots of different versions, and manufacture them individually “on demand” without the use of tools to ensure optimum function, safety and weight. This is fundamentally new in the industry.

Frank Herzog: I share this assessment in the medium term. But I also think that it must be clear that when it comes to design, as with the NextGen spaceframe here, we will have to adopt completely new approaches to implement additive manufacturing more strongly in the automotive sector. The integration of functions, such as cooling capacity, may also be an important piece in the jigsaw. An additively manufactured product must be consistently developed starting from the performance criteria. If it can do more than the old product and also deliver lower costs and greater flexibility, it will appeal to people.

Editorial team: Will these new approaches be able to invigorate the development cycles and the range of models? What potential results in the structure of costs and the final price of the vehicle?

Sergio Raso: The great flexibility of the Spaceframe design enables parametric construction of the car frame. In principle, we are pushing open a window for a much wider range of models or even personalized cars. What I am certain of is that the cost structure can be approved with this strategic approach – and therefore hopefully also lower the final costs of the vehicle for the purchaser.

Frank Herzog: But the question in general would also be where is the automotive industry heading? Does it want to embrace volume strategies or will there not also be a demand in future for individualized car concepts in order to attract purchasers? In the latter scenario, and it is possible that both trends will exist side by side; additive manufacturing will be able to lead the way in some respects.

Editorial team: What possibilities do you see for future components for functional integration in cars, such as cooling functions, or the ability to construct more powerful and capable components?

Martin Hillebrecht: Without this functional added value, which I take for granted in any concept, no matter which one, it will scarcely be possible to justify the currently high additive manufacturing costs.

Editorial team: Critics say that the current build envelope limits and assembly speeds in 3D manufacturing restrict the possibilities. How do you assess this discussion?

Claus Emmelmann: At the present time, the productivity of the process for certain applications, such as large-scale automotive production, is limited. To that extent, the argument is correct. In sectors such as medical technology or aviation, the process is already heavily used. I forecast that the technology will see a significant leap in productivity over the coming years and thus will also manage to gradually become an attractive proposition for large-scale automotive manufacturing. Laser Zentrum Nord works together closely with its partners to develop new machine and automation concepts designed to make this possible.

Martin Hillebrecht: The build envelopes are already more or less sufficient today, but typical materials are still not adequately developed and are much too expensive. We would like to see additive manufacturing processes which enable an assembly speed that is maybe 100 times greater while still retaining the same surface quality. Tell the plant manufacturers: Keep going down the path you have embarked upon.

Sergio Raso: This restriction in terms of the build envelope and prices will be reduced in the near future thanks to the introduction of new laser systems for additive manufacturing with greater power and enhanced build-up rates. However, the hybrid design with nodes and profiles which has been adopted for long dimensions already gives a hint of an economical approach today. The issue is in flux.

Frank Herzog: Let’s take a look back and a look ahead. The assembly speeds have already increased a great deal thanks to Multilaser technology and increasing laser power. But it should also be borne in mind that each new laser source increases the complexity of the process and therefore also its susceptibility to errors. From today’s point of view, I do not think that purely quantitative approaches are the best way to go. As we demonstrate with our AM Factory of Tomorrow, from our perspective the vital thing is to focus on downtimes during the production process with the ultimate aim of minimizing them. They are usually associated with manual tasks in upstream and downstream stages of the process, such as supplying new powder or finishing the products. This is where in the first instance we see a much more important starting point for advancing our process to make it viable for economic mass production, even if the laser power certainly still offers plenty of scope to be increased. In addition, qualitative efforts are paramount for us because an additively manufactured product should of course also be able to win people over just in terms of its quality. If this basis is easy to control, progress can be made when it comes to performance. I would like to support the comment made by Dr. Hillebrecht that the build envelopes are already large enough. Concept Laser offers the world’s largest build envelope (800 x 400 x 500 mm3) in the X line 2000R. Even larger parts may perhaps be possible, but with very large parts we start to reach the limits of physics: The stresses in the part would increase. This cannot be controlled by procedures today. One alternative is then always to use joining techniques in order, for example, to join together very narrow, long parts in a modular fashion. Despite all the euphoria surrounding additive manufacturing, we would be well advised to look to the future with realism and a sense of proportion.

Editorial team: Let’s look at the issue of the quality of 3D components. How do you assess the standard of traditional manufacturing methods compared to additive methods?

Martin Hillebrecht: Standards and quality requirements are being drawn up by industry experts and will undoubtedly also be based on the standards used for traditional manufacturing methods.

Frank Herzog: It has to be said though: We have a more or less “blank canvas” as far as the additive manufacturing solutions of the future are concerned. But the NextGen spaceframe sends a sufficiently bold signal to the automotive industry to look at the issue more closely in terms of design. Maybe I see things too cautiously, but what we need in the future is a “3D generation”, engineers and designers who are confident working with 3D printing, because young people today can barely imagine a life without their smartphone or the internet. The “3D generation” is certainly still in its infancy, but it also needs specific projects in order to prove itself. However, I am confident that this “3D generation” will search for its own themes.

Sergio Raso: 3D laser material processing has become established worldwide as a reliable technology. From my point of view, it is better able to guarantee quality levels of the process and products than traditional manufacturing solutions. In this scenario, additive manufacturing processes are expected to take us to an even higher level of quality. Based on the digital process, the technology will be very capable of being integrated into digital production in the future. Along with the theme of automation, there is plenty of interesting potential for “Industry 4.0” here.

Editorial team: In conclusion, please let’s look ahead to the future. Which additive parts will be conceivable in the automotive sector in the next decade?

Martin Hillebrecht: Besides the traditional production of prototype parts, e.g. of cast parts, additive manufacturing will make it possible to create very complex, functionally integrated and highly efficient structures that cannot be produced using other methods. So it is worth exploring niche areas and, apart from motor racing and ultra lightweight construction, looking for future solutions in the context of specific requirements, e.g. electric mobility. They can then be fleshed out with us as the independent development company for the automotive industry.

Frank Herzog: (Laughs) Let’s see what sort of mad ideas the “3D generation” have in their heads. When we founded Concept Laser 16 years ago, we too had mad ideas in our heads. We in the development department have since been more than positively surprised. And that is a good thing.

Sergio Raso: I am not a prophet. According to the scientists from the ESA, mankind will only be able to embark on missions such as a manned mission to Mars if technologies become available for repairing the human body on the journey there. Could the driver of a vehicle accept this as a politically correct answer? All I want to say is that in the future we will have to accept solutions which cannot be transmitted today. The fact is that 3D printing on space stations is already being explored by NASA. And whatever happens, from a cosmic perspective there is a great deal of future ahead of us.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.