Aleksandr Novakovskiy is CEO and founder of Ukraine’s first 3D printer manufacturer, 3DP. He will also join the second forum of innovative technologies, InnoTech Ukraine 2016, as as speaker. The event will take place from March 11 to 12 in Kiev and will unite manufacturers and end consumers, startup developers and investors, ideas and further implementation, as well as turn the attention of state institutions to the necessity of promoting a segment of innovations in Ukraine.

How did you first make contact with additive technologies or 3D printing?

Alexandr: Well, I became addicted to additive technologies thanks to unfamous Cody Willson. I was blown away, when I saw 3d-printed and fully functional AR-15 receiver and the ammo clip (that was a year before he created his “Liberator” one-shot handgun).

Alexandr: Well, I became addicted to additive technologies thanks to unfamous Cody Willson. I was blown away, when I saw 3d-printed and fully functional AR-15 receiver and the ammo clip (that was a year before he created his “Liberator” one-shot handgun).

Could you give us a short introduction to your 3D printer line?

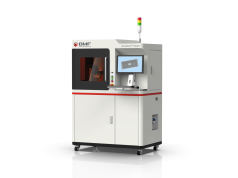

We are focused on the production of untraditional non-cartesian machines. Currently, quite a bunch of Delta-Style 3D-printers are available to the public: Kossack3d – entry level FDM machine, which workspace is 200x200x250mm and more professional Kossack Pro, which goes in an enclosure and has a 300x300x400mm volume. Both models can provide 50µm precision and can consume almost any type of filament available on the 3D printing market. Plus, Kossacks can be equipped with multiple extruders and produce multi-material/multi-color prints. For more precise prints (i.e. jewelry), we’re providing clients with a DLP system-chassis. In this case they can get 6µm resolution for their model.

In which industries do you see the most potential for your products? Did additive technology already entered industries you didn´t think of?

First of all, 3D-printing is designed for prototyping, as in this case the constructor can pass the proof of concept stage for the new product in no time, just by printing a prototype versions over and over till he gets the best match. So any constructor or hobbyist maker is the first in line for additive technology utilisation. Same goes for architects, jewelers, dentists – almost any profession, connected to design. Nowadays, even artists and fashion designers are using 3D-printers in their everyday routine. Possibilities of additive technologies are limitless for education… Nobody knows in which field this technology is going to be used next. We’re just making tools, and only the human imagination can set the limit for that.

How would you describe the connections in the 3D Printing ecosystem (hardware, software, materials,…)? Is one part of the ecosystem that is more important than the others?

All of these fields are influencing each other: emerging of affordable 3D-printers started the creation of cheap filaments and, for example, when somebody will create cheap metal filament – we’re going to get affordable metal-sintering printers. Same goes to software, which improves user experience.

What are the next steps for 3dP Ltd.? Can you tell us something about future plans?

These are huge. But for now, the little sneak-peek we can disclose is that we’re opening the 3D-printing studio for everyone, where any individual can learn how-to and actually use 3D-printers on an hourly basis. This is not a FabLab, as we’re focusing on additive machines only, so the client won’t be overwhelmed. Also, we’re working on the creation of affordable SLS system.

Find out who else we spoke to in our 5Questions interviews series of industry experts.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.