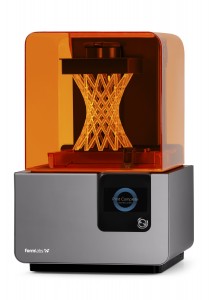

In our interview series 5Questions we ask international experts from the additive manufacturing space five questions. This time Michael Sorkin spoke to us about his origins in the 3D printing industry and about Formlabs’ new Form 2 3D printer.

Michael Sorkin joined Formlabs in mid 2015 as their General Manager for Formlabs GmbH, the European headquarter based in Berlin. Just two month later Formlabs released their Form 2 3D printer. The Form 2 is the successor of the Form 1+ which is the evolution of the Form 1, that Formlabs  originally funded via Kickstarter.

originally funded via Kickstarter.

Before Michael joined Formlabs, he founded iGo3D, as a leading distributor and retailer for 3D printers in Europa.

How did you first learn about additive technologies or 3D printing?

Michael Sorkin: The world of additive manufacturing has fascinated me from the very start. In 2012, I paid a spontaneous visit to the University of Architecture and Design and saw a DIY Desktop 3D printer. I was immediately struck by this “tangible” technology and its unlimited potential.

Back then, mass media closely linked 3D printing with the printing of weapons and organs. There were few reports about “real-world” applications, and there was a lack of knowledge about 3D printing. However, the first machines were more capable than that! They made our ideas concrete and inspired creativity in a diverse group of people. This thrilling period was, in my opinion, the perfect breeding ground for startups and innovative projects in 3D printing that still flourish today. This period gave birth to companies like iGo3D and Formlabs.

In which industries do you see the most potential for your product line? Did additive technology already infiltrate industries you were not aware of?

Our desktop stereolithography 3D printers are already used in many industries and by a diverse group of users. We basically focus on common core markets like product design, prototyping, and manufacturing. We are also noticing more and more interest in research, the dental market, and the jewelry industry. New areas of application are on the horizon.

How would you describe the connections in the 3D printing ecosystem (hardware, software, materials, etc.)? Is there one part of the ecosystem that is more important than the others?

From my experience, all these components have completely equal weight. They are necessary and valuable, and only together can they merge into one unique solution. Most of the customers who contact us or our partners don’t want to buy just another 3D printer but a fully equipped solution that enables them to solve problems & challenges successfully and economically. A 3D printer without the right software or the right material is as useful as a sword without a blade.

In December you officially started shipping the new Form 2 to your customers. How did customers react to the improvements?

It is never too early to talk about our success. Long before the introduction of the Form 2, we were working closely with many beta testers and customers to perfect our products. The resulting Form 2 ecosystem has been designed, planned, and manufactured in response to direct customer feedback. The first customer reactions have been overwhelmingly positive.

It is never too early to talk about our success. Long before the introduction of the Form 2, we were working closely with many beta testers and customers to perfect our products. The resulting Form 2 ecosystem has been designed, planned, and manufactured in response to direct customer feedback. The first customer reactions have been overwhelmingly positive.

Right now, we are experiencing a strong, continuous demand that we are working to satisfy with all of our resources. Despite the incredible start, we work incessantly toward our goal: to produce and distribute the world’s best solutions in the digital fabrication industry!

What are the next steps for Formlabs in Europe and beyond?

For the past three months, we focused on two crucial columns: the team and the EU distribution network. They form the foundation that enables us to learn about our European customers and their needs and to spread brand awareness. Today, we have an efficient office, many partners, a revolutionary product, and an incredibly talented team that is eager to lead the European 3D printing industry and to set new industry standards.

It will be an exciting journey, and I am very proud to be a part of this amazing team on the forefront of this roller coaster industry!

If you are interested in more news about Formlabs you can find them here in our news section or on the homepage of the manufacturer.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.