Amnovis has provided a comprehensive presentation of its qualified titanium 3D printing processes for Ti Grade 1 and Ti-6Al-4V Grade 23 in its FDA Master File. This proactive approach by Amnovis aims to address typical FDA concerns related to these processes, thereby facilitating regulatory submissions for 3D printed titanium implants in the US.

The FDA Master File details the outstanding expertise of Amnovis’ founders in the field of titanium 3D printing, as well as the operational excellence of the entire Amnovis team.

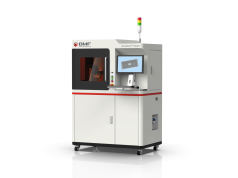

Amnovis is widely recognized as an innovative contract manufacturer for additive manufacturing (AM). As far back as 2008, the founders of Amnovis have been involved in the production of high-quality AM products and pioneered the use of the Laser Powder Bedding (LPBF) process for the 3D printing of titanium medical devices. With their extensive expertise and experience, Amnovis is able to remove obstacles in the development, validation and manufacturing of medical products.

A common challenge for medical device manufacturers is answering FDA concerns related to the 3D printing process in their regulatory submissions. To avoid delays and difficulties in gaining approval for the U.S. market, Amnovis has contributed its extensive expertise in AM processes and 3D printing technology for titanium to the FDA Master File. This greatly facilitates regulatory submissions for 3D printed titanium implants for Amnovis’ customers. The Master File addresses key innovative aspects of Amnovis’ qualified 3D printing processes for standard and custom devices using validated Ti Grade 1 and Ti-6Al-4V Grade 23 materials.

Ruben Wauthle, Amnovis CEO & Co-founder: “Having an FDA Master File is a new milestone for our company and perfectly fits with our strategy of manufacturing high-end products for quality-critical and high-tech applications. Guided by our commitment to quality, we are ISO 13485 certified and combine our thorough understanding of product specifications and process capabilities with state-of-the-art metrology and material testing methods. As a result, we enable our customers to shorten their time-to-market and to eliminate costs related to non-conforming parts.”

“As a company, we continuously want to redefine the state-of-the-art for 3D printed medical devices, and at the same time make our unique process knowhow and expertise more readily available to customers worldwide, like we do with our FDA Master File. In the end, this helps the adoption of 3D printed medical devices, which offer more added value for patients and provide them higher degrees of comfort and mobility.”

Find out more about Amnovis at amnovis.com.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.