3D printing specialist AddUp has joined the $1.5 million “Development of Manufacturing, Heat Treatment, and Surface Finishing Guidelines to Yield Ready-to-Use IN- 718 Additive Manufacturing Components” research contract through the United States Air Force (USAF) and Small Business Innovation Research (SBIR) program led by REM Surface Engineering (REM).

The USAF is constantly looking for innovative solutions to improve its weapons systems. The SBIR-funded project is using Laser Powder Bed Fusion (LPBF) and surface finishing technologies to produce IN-718 components for legacy weapon systems. The effects of various heat treatment and pressure parameters on mechanical properties such as tensile strength and fatigue life are being investigated.

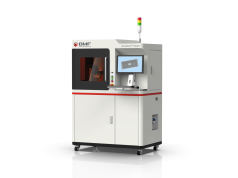

IN-718, a nickel superalloy known for its high temperature and corrosion resistance, plays an important role in component reliability and longevity. AddUp’s FormUp 350 machine enables surface finish enhancement, resulting in improved fatigue properties of the IN-718 material.

AddUp will work with Zeda to produce IN-718 fatigue specimens. These samples will be used to determine the expected material properties of LPBF components with different surface qualities.

The project is a significant step toward improving USAF performance and mission readiness. It aims to improve the reliability and cost-effectiveness of aerospace and defense components and ensure that mission-critical operations can run smoothly.

Find out more about AddUp at addupsolutions.com.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.