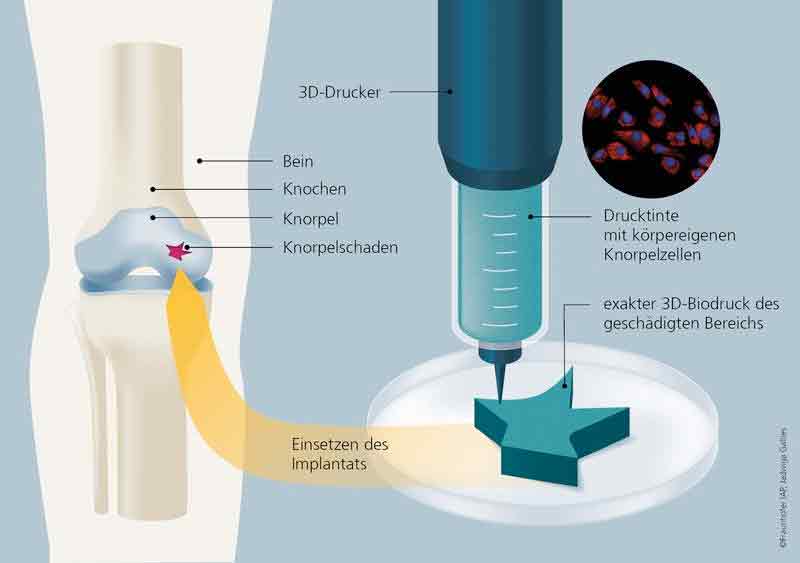

Sport can lead to injuries if not performed correctly, often affecting the cartilage in the joints. Untreated cartilage defects can lead to osteoarthritis at older age, for which there is currently no effective treatment. Personalized cartilage cell implants made by 3D printing should provide a remedy in future. Special printing inks containing the body’s own cartilage cells are being developed for this purpose. The four-year project at the Fraunhofer Institute for Applied Polymer Research IAP and the Brandenburg University of Technology Cottbus-Senftenberg BTU started in January 2024 and is being funded by the Federal Ministry of Education and Research (BMBF) with around 2 million euros.

Cartilage damage in the knee or other joints shows little ability for self-healing, as cartilage has no blood vessels. A proven method for treating such defects is the transplantation of the body’s own cartilage cells. This involves taking healthy cartilage cells from a less stressed area of the affected joint, multiplying them in the laboratory and then transplanting them into the damaged area of cartilage. Although this technique helps to alleviate pain, improve joint function and slow down the progression of cartilage damage, it cannot be used in all cases. Alternatives are being sought for larger cartilage defects in particular.

3D bioprinting, also known as bioprinting, opens up enormous potential here. This manufacturing technology makes it possible to produce biological tissue in a three-dimensional format. Like conventional additive manufacturing processes, 3D bioprinting involves building up layers of materials to form a specific structure. However, biomaterials are used as printing inks, in which living cells can even be embedded.

Bioinks for 3D bioprinting

“In the BioPol-3D project, we are developing inks for 3D bioprinting that already contain the patient’s cartilage cells. The cells are embedded in a hydrogel. These bioinks can be cross-linked or stabilised during or after printing to create the desired shape and structure,” explains Professor Ruben R. Rosencrantz, head of the “Life Science and Bioprocesses” research division at the Fraunhofer IAP and holder of the chair “Biofunctional Polymer Materials” at BTU.

The researchers are using glycopolymers, among other materials, as a hydrogel matrix. These are specially synthesised and are ideally suited to replicating the natural environment of cartilage cells in the body. However, glycopolymers have not yet been used as a construction material. As part of the project, the team is investigating how suitable the glycopolymers are for 3D bioprinting in terms of their material and processing properties and optimising them for this purpose.

“For the development of these glycopolymers, we are combining our chemical and biotechnological expertise at the Fraunhofer IAP in a unique way. This combination plays a decisive role for BioPol-3D, as the material optimisation must be very precisely matched to the biological processes. “, says Rosencrantz.

“Our approach to printing the cartilage cells goes beyond conventional methods, because we mould the biological component – the cartilage cells – directly. In other words, we don’t first print a scaffold on which cells are later placed,” adds BTU colleague Professor Ursula Anderer, who hold the chair for “Cell Biology and Tissue Engineering”.

“There are a number of parameters that we have to take into account in order to develop printable inks: the sensitive cartilage cells must remain vital, the inks must be biocompatible and biodegradable in a controlled manner and, finally, the desired cartilage shape must have a high degree of stability and strength. Our aim is to establish an advanced 3D cell culture for the treatment of cartilage damage and at the same time revolutionise the production of such molded bodies through additive manufacturing,” says Anderer.

3D bioprinting strengthens Lusatia’s innovative power

3D bioprinting is an up-and-coming market that is attracting numerous small and medium-sized companies and start-ups – a development that will also benefit Lusatia.

“The intensive collaboration with the BTU and the project group “Biologisation/Biofunctionalisation of Polymers BioPol” at the Fraunhofer IAP offers great potential for developing even more innovative materials for 3D bioprinting in the future. If these materials and processes prove successful, we will also be able to open up applications in the fields of sensor technology or cosmetics in the future. This strengthens the region’s innovative power in the field of 3D printing and promotes structural change activities in Lusatia,” says Rosencrantz.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.