Eggshells, which consist mainly of calcium carbonate, are used in numerous areas – from feed supplements to pest control in the garden. But now researchers are also using eggshells to grow tissue for implants that can replace damaged or diseased bone and cartilage. This groundbreaking research could revolutionize medicine.

Led by Prof. Dr. Gulden Camci-Unal of the Department of Chemical Engineering at the University of Massachusetts Lowell, the research team has developed this approach to reusing eggshells. Eggshells, which are primarily composed of calcium carbonate, are used in a variety of applications, but their potential in medicine has been largely overlooked. Camci-Unal and her team have been working intensively since 2016 to use finely crushed eggshells to create tiny 3D structures, known as scaffolds, on which bone cells can grow and multiply.

“Each year, millions of tons of eggshells are routinely discarded worldwide. Since they are considered as waste, their potential as unconventional biomaterial is largely overlooked in the medical field,” says Camci-Unal, who is the Robert and Gail Ward Endowed Professor in Biomedical Materials Development. “Our goal is to repurpose this eggshell waste for personalized medicine. Eggshells possess minerals that are also found in human bones, making them a promising candidate for biomedical applications,” she says.

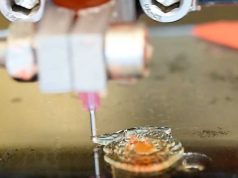

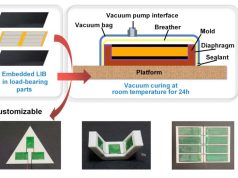

In a further step, the researchers have now used a biocompatible and biodegradable synthetic polymer to reinforce these eggshell-based scaffolds. Using 3D printing technology, they can produce precisely shaped structures for implants that are ideal for the repair and regeneration of damaged tissue. This technology makes it possible to design patient-specific implants that are precisely tailored to individual needs.

“Lab-grown bone grafts reinforced with eggshell microparticles not only support bone growth and healing, but they can also lessen the risk of complications, thereby reducing hospital stay and hastening recovery,” she says.

A significant advantage of this method is the sustainable use of eggshells, millions of tons of which are disposed of as waste worldwide. As eggshells contain minerals that are also found in human bones, they are promising candidates for biomedical applications.

“3D printing can mimic the architectural and biological features of natural tissues more effectively than traditional methods,” she says. “It allows us to design patient-specific implants and precisely fabricate scaffolds in the clinically needed shapes and sizes.”

The researchers use a thermoplastic polymer called polycaprolactone mixed with eggshell microparticles to create composite pellets. These pellets are then melted and used as “ink” in a 3D printer to build up the scaffold structures layer by layer. The resulting structures have higher mechanical strength and load-bearing capacity, making them particularly suitable for orthopaedic applications.

“The precision of 3D printing technology will enable us to design customized and intricate structures tailored to the individual patient’s needs,” she notes. “For instance, a patient’s bone defect can be scanned with a laser, and then an eggshell-based implant can be 3D-printed to exactly fit in that defect.”

The research team is now planning to further expand the work and attract new partners and external funding in order to transfer this promising technology into clinical practice. The results of the study so far have been published in the journal ACS Applied Materials & Interfaces and could make important contributions to bone regeneration and other medical applications in the future.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.