6K Additive has been selected by the RTX Technology Research Center (RTRC) and the University of Arizona for the America Makes and National Center for Defense Manufacturing and Machining (NCDMM) EARTH project.

The EARTH project is funded by the U.S. Department of Defense’s National Center for Defense Manufacturing and Machining (NCDMM) with $1.2 million in funding. The goal is to significantly improve energy efficiency and material utilization in the production of components for the aerospace and defense industry through the use of advanced additive manufacturing techniques.

“RTX is pursuing sustainable additive manufacturing processes to produce next-generation aerospace and defense products as well as support out-of-production part replacement. As part of this plan, our goal is to introduce hundreds of additively manufactured parts to the market over the next several years,” said Brian Fisher, principal investigator for the POSAM project, RTX. “We selected 6K Additive because of their process of converting revert and used powder into high-value, premium powder, which helps us to measure quality and carbon footprint in the same project. These advances not only make additive manufacturing more sustainable but will drive down costs for production at scale.”

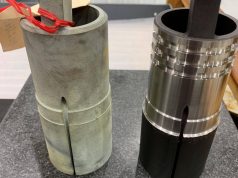

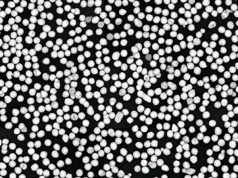

A key aspect of the project is to increase the deposition rate in additive manufacturing by a factor of two, while at the same time reducing the energy required to produce the starting material by 75%. This could halve the total energy consumption in the production of a component using additive manufacturing. 6K Additive brings to this project its expertise in the sustainable production of metal powders made from recycled material using a proprietary process. These powders, including titanium alloys such as Ti-6Al-4V, will be optimized for additive manufacturing to maximize deposition rate, reusability and recyclability.

“Time and again, 6K Additive continues to prove itself as having one of the market’s only tested processes to achieve new levels of sustainability and quality in a highly regulated market in aerospace and defense. And much of this success is driven by our proprietary technology for processing titanium and refractory metals at scale – powering both customers and the environment by recycling scrap streams back to premium powders,” said Frank Roberts, President of 6K Additive. “The project award by the prestigious team at America Makes in collaboration with a leading defense and aerospace prime in RTX and a well-respected AM research institution in the University of Arizona further proves that 6K Additive is leading the sustainable, high-quality powder production for additive manufacturing. We’re honored to be selected for this important and market-critical project.”

6K Additive’s innovative method of converting recycled materials into high-quality powders is at the heart of the project.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.