3D printing enthusiasts know the problem: almost empty filament spools take up valuable space but contain too little material for larger projects. The YouTube channel CNC Kitchen presents various solutions to this dilemma in a recent video.

Modern 3D printers already offer integrated functions for utilising filament remnants. Filament detection sensors make it possible to pause printing when the spool is empty and reload new material. More advanced systems such as Bambu Lab’s Automatic Material System (AMS) or the Prusa XL’s spool join function even automate this process.

Bambu Lab’s AMS, originally designed for multi-colour printing, can automatically switch between spools with the ‘filament backup’ option activated. The Prusa XL’s spool join function allows multiple spools to be linked for one print job.

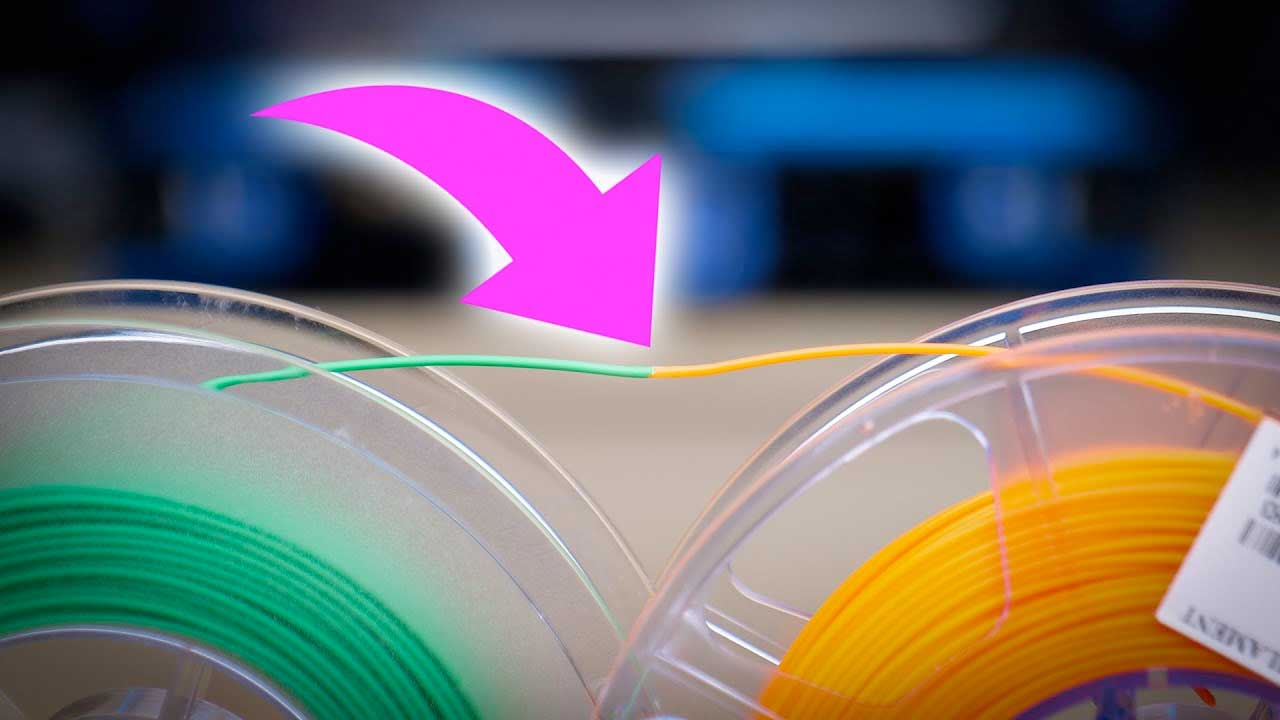

For owners of conventional 3D printers, CNC Kitchen presents the solution: the SUNLU Filament Connector. This compact, USB-powered device enables filament ends to be connected precisely. It uses thin PTFE tubes to align the filament ends and an integrated heater for fusing.

The SUNLU Tool works at temperatures up to 240°C and is suitable for common filaments such as PLA, ABS, ASA, polycarbonate and nylon. Operation requires some practice to achieve optimum results. Users must pay attention to the correct positioning of the filament ends and the correct pressure during melting.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.