Hexagon Manufacturing Intelligence has introduced a new generation of handheld 3D scanners that add new, convenient functionalities for flexible measurements to its wide range of inspection devices. The new ATLASCAN Max and MARVELSCAN models enable engineers and production workers to accurately scan objects in a variety of environments – both inside and outside the factory floor.

The ATLASCAN Max and MARVELSCAN devices are specifically designed to measure parts in environments where traditional metrology is not used, such as automotive, rail transportation, industrial facilities and restoration projects.

“Today, manufacturing and design teams use up-to-date 3D scans throughout the product lifecycle. This means that almost everyone needs to take a metrologically accurate scan of a part regardless of their location,” says Pirmin Bitzi, General Manager for Portable Measuring Devices at Hexagon. “Our first portable 3D scanners allow customers to digitize parts without having to worry about mounting or environmental conditions. MARVELSCAN’s state-of-the-art, integrated photogrammetry system aligns to reference points, eliminating the need for stickers. The wireless and ergonomic scanners enable seamless, instant scanning in the workshop or shipyard.”

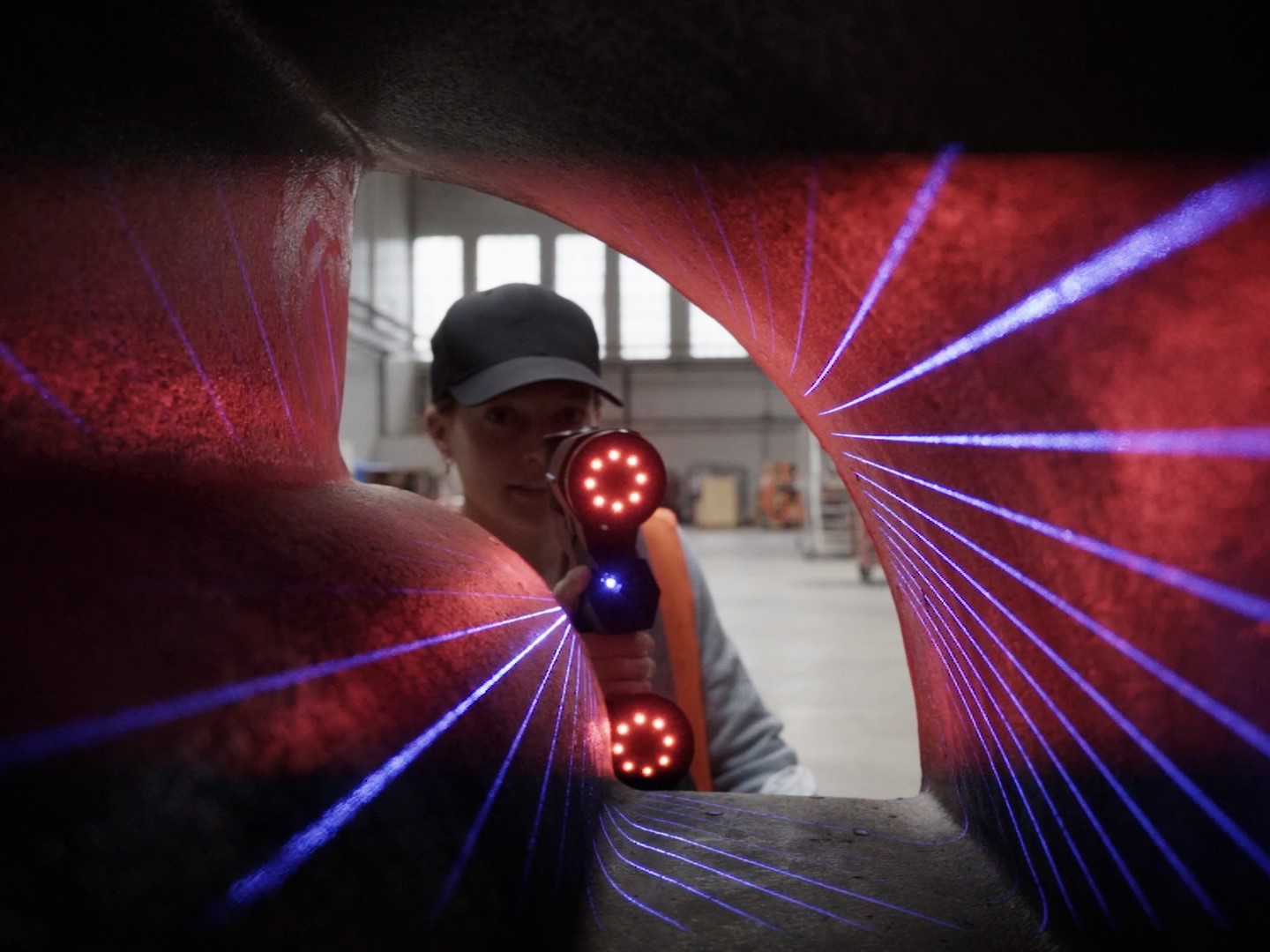

Users of ATLASCAN Max and MARVELSCAN can optimize their workflows with ergonomic, thumb-operated controls and perform 3D scanning processes even in confined spaces, harsh environments or outdoors. As no access to a control PC is required during measurement, multi-mode scanning enables efficient measurement of different feature types and surfaces.

Users can scan open surfaces in standard mode and then quickly switch to fine mode to achieve higher resolution on intricate features. Automatic data capture in different modes is combined into a single, editable point cloud. The devices also offer a special capture mode that enables instant data capture of multiple holes and slots in one shot, further increasing productivity.

The MARVELSCAN sets new standards for productivity in 3D scanning as it features integrated photogrammetry, which enables scanning without the need to pre-define measurement points. This is ideal for scanning large parts or parts in large quantities, as the time-consuming setting of measuring points is no longer necessary.

Both scanners are ideal for integration into automated inspection processes with industrial robots or cobots.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.