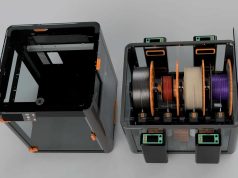

YouTuber Robert Murray-Smith has unveiled a remarkable project: a fully 3D-printed cable winding machine. This development demonstrates the potential of 3D printing for the production of functional devices in the home.

The machine is based on a complex mechanism originally designed for industrial applications such as pipe making and cable wrapping. Murray-Smith adapted this design for 3D printing and optimised it for home use.

A centrepiece of the design is an external gear that Murray-Smith designed in Tinkercad. He deliberately chose external rather than internal gearing to simplify the design process. The gear consists of two meshing gears that ensure a continuous drive.

Murray-Smith made some pragmatic decisions in the design. He dispensed with ball bearings in favour of rubbing plastic parts, which limits the service life of the machine but is sufficient for occasional applications. He also replaced the commonly used chain drive with a direct gear drive.

The machine was initially designed for manual operation, but can easily be converted to a motorised drive. Murray-Smith emphasises that such design decisions demonstrate the flexibility of 3D printing. Users can customise the design to their specific needs.

In a practical test, the machine demonstrated its functionality, although Murray-Smith conceded that a motorised drive would make it easier to operate. He plans to further optimise and possibly scale up the design.

The 3D print files for the cable tying machine are freely available on Thingiverse. Interested parties can rebuild, modify and further develop the project.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.