YouTuber Robert Murray-Smith has unveiled an interesting project that combines the principles of historical hit-and-miss motors with modern 3D printing technology and electronics. The result is a compact pulse motor that can be designed, printed and assembled in less than a day.

Hit-and-miss motors, which were widely used between the 1880s and 1950s, utilised a large flywheel to store energy. The new pulse motor takes this concept and combines it with a simple electric drive.

At the heart of the motor is a pendulum clock mechanism, which is commercially available for around 5 euros. This already contains a compact circuit with coil and integrated circuit, which functions as a transistor, capacitor and resistor. Murray-Smith skilfully uses this prefabricated unit as the drive for his 3D-printed motor.

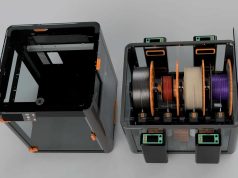

The motor’s structure comprises a 3D-printed housing, a flywheel with embedded magnets and an axle with needle bearings. The magnets in the flywheel are arranged in such a way that they harmonise with the electronics of the pendulum clock mechanism. When the magnets are pulled past the coil, an impulse is generated that causes the flywheel to rotate.

The 3D print files for the motor can be found free of charge on the Thingiverse platform. Interested hobbyists can easily recreate the project and possibly develop it further.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.