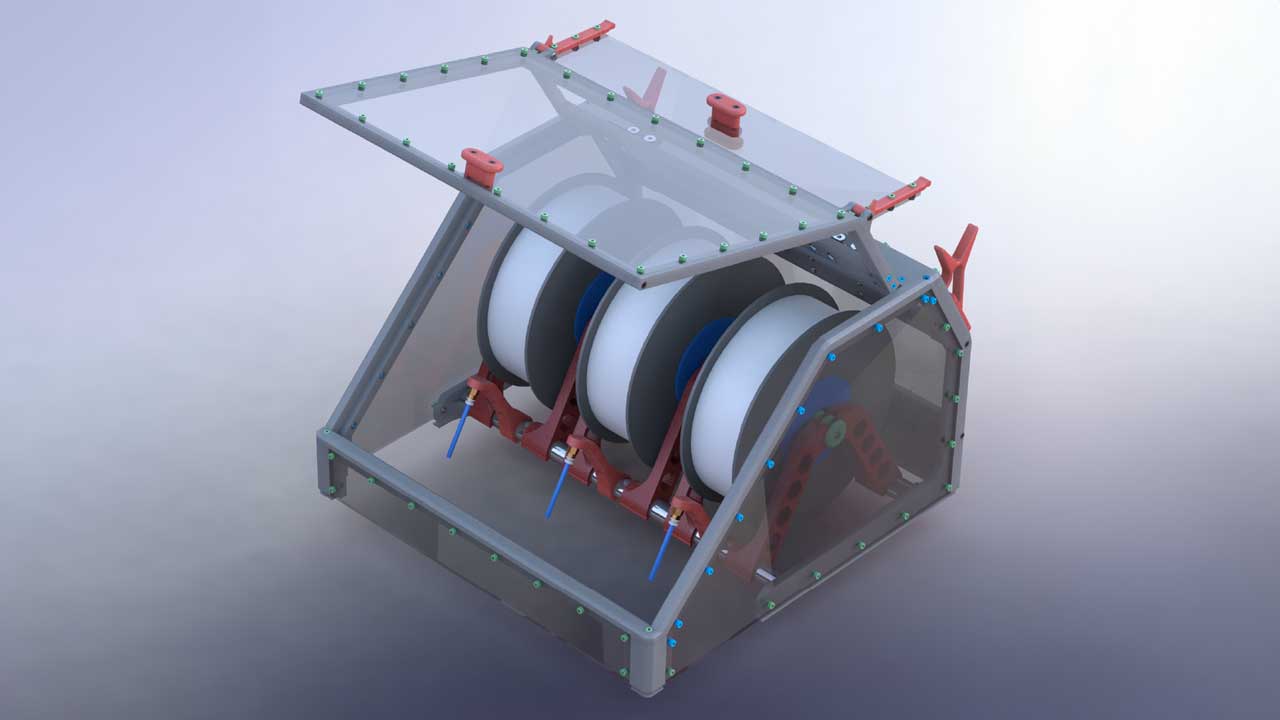

K1 Max is one of the most popular 3D printers from the popular manufacturer Creality. The Maker Digital Inventor has introduced the “Multi-Filament System for Creality K1 Max” (MFS K1M) project for the 3D printer, which promises owners of the Creality K1 Max 3D printer a significant simplification when changing filament. The self-built attachment enables the convenient handling of up to three filament rolls, each weighing 1 kg.

As the developer explains, the filament feeder on the K1 Max is positioned unfavorably at the rear. This not only makes it difficult to change the filament, but also makes it impossible to check whether the filament is about to run out. The MFS K1M provides a remedy here.

Three spools can easily be accommodated in the system’s chamber. The waste heat from the printer ensures that the filaments are dried in the meantime – practical in high humidity conditions. According to the developers, the weight of the system also makes the printer more stable.

In addition to the 3D-printed components, various screws, nuts and metal parts are required for the replica. A list of materials is included in the assembly instructions. Digital Inventor sells these instructions with the required STL files for around 25 US dollars. In addition, there are estimated material costs of 50 to 100 US dollars.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.