Thermoplastic elastomers (TPE) are becoming increasingly important in 3D printing. This group of materials combines the processability of thermoplastics with the elastic properties of rubber. In a detailed test, the YouTube channel CNC Kitchen examined various TPE variants for their mechanical properties and processability.

TPEs include various subgroups such as TPU, TPA and TPC. The Shore hardness serves as an important indicator of flexibility. Materials from 60A (very soft) to 99A (hard) were examined in the test.

The processing of TPEs requires some adjustments. Drying the hygroscopic material before printing is crucial. The printing speed should be reduced and the retraction increased. A glue-stick layer on the print bed prevents excessive adhesion.

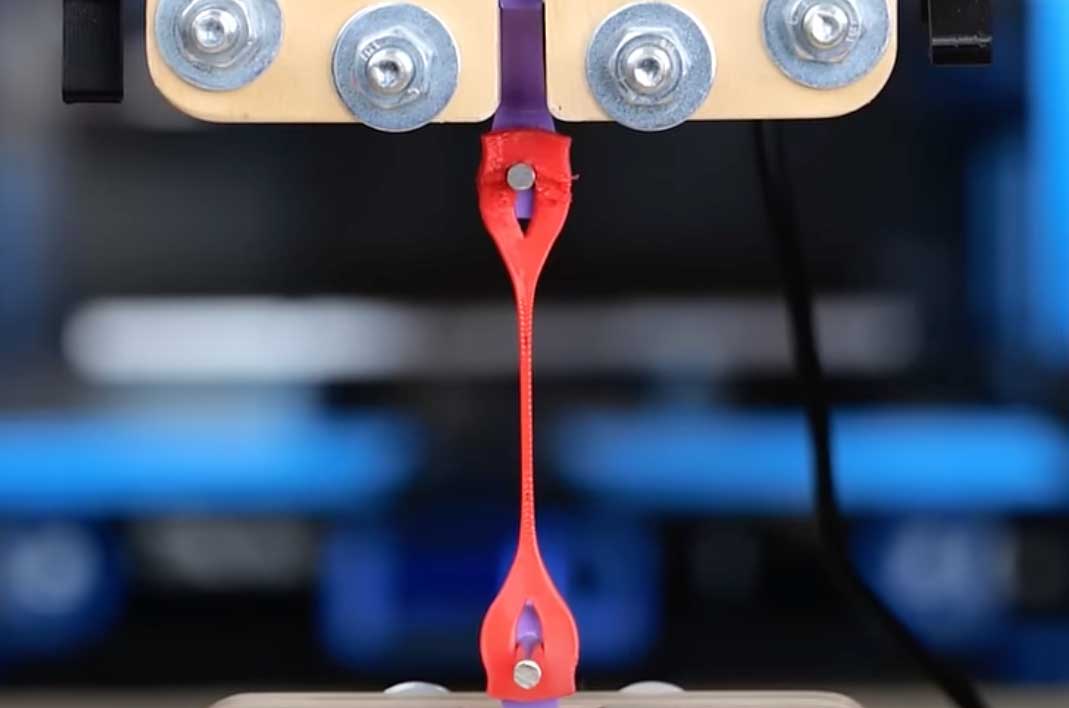

In tensile tests, the TPEs showed exceptional elasticity. The strength was significantly lower than that of PLA, but the layer adhesion was excellent. Fiber-reinforced variants achieved higher strengths, but lost flexibility.

The results for friction and elasticity were particularly interesting. Softer materials tended to have higher coefficients of friction. In terms of bounce height, some TPC and TPA variants surprised with very good values.

TPEs are suitable for a wide range of applications such as seals, dampers or flexible joints. Their temperature resistance is lower than that of rubber or silicone. However, with careful material selection and adapted design, impressive components can be realized.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.