Oqton, a software provider that helps manufacturers drive innovation and efficiency through intelligent production automation, has worked closely with EOS to achieve tight integration of its Build Quality Suite into EOSCONNECT Core.

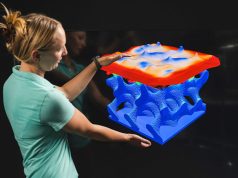

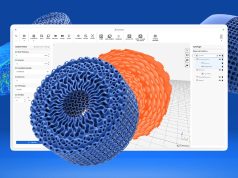

The Oqton Build Quality Suite is an AI-powered solution for metal powder bed printers that monitors the entire manufacturing process to detect and correct anomalies and defects at an early stage. Seamless integration with EOS software gives users complete end-to-end traceability of their additively manufactured parts, helping to meet stringent quality standards. In addition, the solution helps lower production costs by reducing material consumption, minimizing waste and improving the efficiency of engineering teams.

“The new Oqton Build Quality suite has the potential to lead to a significant leap in terms of quality assessment of additively manufactured metal components,” said Rüdiger Herfrid , product manager, software, EOS GmbH. “The ease of use and automatic reporting capabilities are a key step towards the end-to-end traceability and assessment of AM parts. EOS customers can now access AI capabilities within the Oqton Build Quality suite, thanks to seamless integration with EOS software and the close collaboration between Oqton as a partner of the EOS Developer Network.”

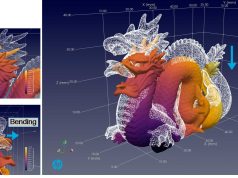

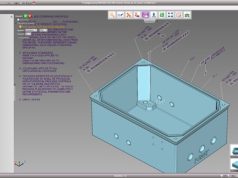

The suite comprises several core modules, including 3DXpert Build Simulation, Manufacturing OS Build Monitoring and 3DXpert Build Inspection. These modules monitor the entire manufacturing process and detect errors that may occur during print preparation, the actual print or in the material. The software uses image and sensor technologies that are already integrated in many metal 3D printers, supplemented by advanced AI algorithms. This eliminates the need for additional hardware investments. Early detection and correction of anomalies ensures that every print job is completed successfully, enabling reliable process repeatability for both prototypes and series production.

“Metal 3D printing has unlocked reliable production of final parts, but ensuring consistent quality was a challenge,” said Kirill Volchek, chief technology officer, Oqton. “This stems from factors such as inconsistent processes, diverse equipment, and multiple software vendors. Oqton’s Build Quality cuts through this complexity, offering a unified, reliable solution. After proving the technology first with 3D Systems, it’s exciting to see adoption of Build Quality expanding, and our collaboration with EOS is a wonderful next step. I’m looking forward to seeing the positive impact this game-changing solution can have in empowering EOS’s customers to achieve unmatched production efficiency.”

With this collaboration, Oqton and EOS aim to further improve the production process for additively manufactured metal parts by enabling more efficient, automated quality control. The integration of the Oqton Build Quality Suite into EOSCONNECT Core is an important step towards increasing efficiency and quality assurance in industrial 3D printing production.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.